PROGRESSIVE EPOXY POLYMERS, INC.

The Marine Epoxy

Boat Epoxy

"Goo" Information Page

** EMAIL / ph 603.435.7199 EST / BUY ONLINE **

|

MARINE NAVIGATION BAR |

Main Home Page ====> * |

Marine Home Page ====> * |

Marine Catalog Contents Page ====> * |

Marine Online Catalog Page ====> * |

Contact Page /Link to Storefront/Ordering * |

This is an Outdated Page * |

HELP Page |

|

Progressive Epoxy Polymers, Inc. |

.. |

.. |

.. |

.. |

.. |

.YOU ARE HERE. |

|

CATEGORY NAVIGATION BAR |

Main Home Page ====> * |

Epoxy Floor Links Page ====> * |

Marine - Boat Related Links Page ====> * |

Epoxy Repair Related Links Page ====> * |

Learn About Epoxies Links ====> * |

Bar Top - Table Top Clear Epoxy ====> * |

GOOGLE SITE SEARCH - Click here

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

** EMAIL / ph 603.435.7199 EST / BUY ONLINE **

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coat time).

|

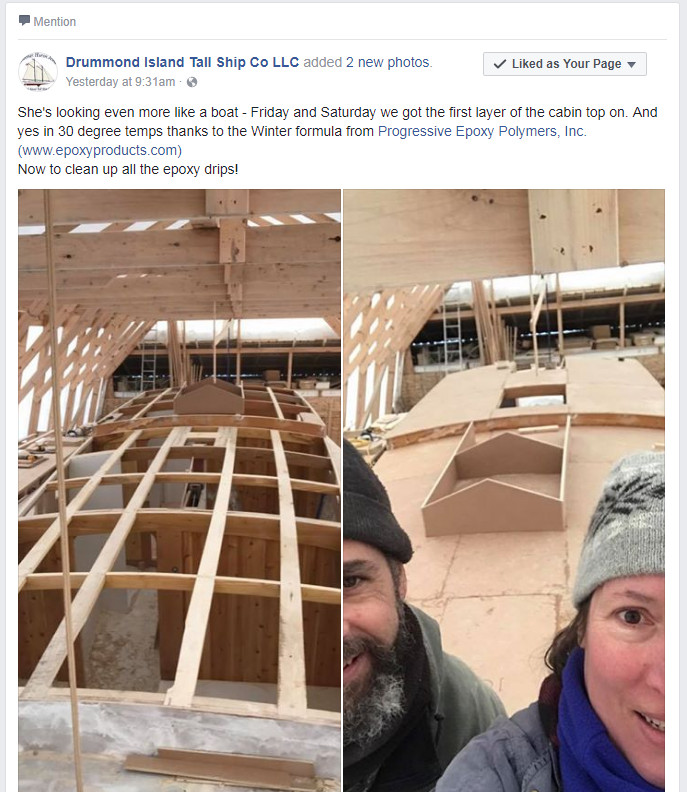

WINTER BOATING: Don't let winter stop you boat repairs/building. Basic No Blush marine epoxy with fast winter cure works down to about 38 degrees. Aluthane mcu aluminum paint can be applied down to about 40 degrees. |

|

You're doing business with: Paul Oman, MS, MBA -- Member since 1994: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings) Former Sailing Instructor -- 1976 Yachting Magazine -- Jr. Article Writing contest 1st place winner -- Boat builder --Founder: Friday Night Kayaking Club -- "Good Old Boat" magazine advertiser -- Boat US Member since DEC 1980 -- A.K.A "The Epoxy Guru" and Professor E. Poxy. 603 435 7199 |

|

WE'RE THE BEST SOURCE FOR ALL BOATING RELATED EPOXIES AND COATING! HERE'S WHY: No matter if your boat repair/building project is sitting in a 39 degree barn or sunk in 10 feet of water in the local harbor, our epoxies can save your day. We have Kevlar (tm) reinforced epoxies, marine non-blushing epoxies with bubble breaker additives (no one else has that!), two part polys in white or clear, and old fashion spar varnish. The clear has massive amounts of UV blockers. Need an epoxy barrier coat or an epoxy sealer/primer for that old weathered fiberglass hull? Does you hull have blisters? Need a thickened epoxy or DIY epoxy thickeners? Does the pontoon boat leak? Need to repair a spongy, rotting deck core? We can do all of that and also save your sinking or sunk boat AND help you build that stitch and glue kayak or 72 foot schooner (they used 200 gallons of our epoxy!). PROGRESSIVE EPOXY POLYMERS INC. (marine catalog) or just call us 603 - 435 -7199 - available nights and weekends. Email anytime. - TOP FAVORITE EPOXIES --- WEB BOAT REPAIR LINKS --- BOAT EYE CANDY! |

|

|

BOAT BUILDING SUPPLIES AND INFO |

|

Call 603-435-7199 help/orders |

|

One of our marine epoxy competitors (now a mere impersonal, product line sub-division within a big industrial corporation) claims a 30% savings in time using non blushing marine epoxies. Non blushing marine epoxies do not require washing or sanding between epoxy coats or top coating with other paints. Note that we offer Basic No Blush marine epoxy with fast, slow and regular curing agents (and it also includes bubble breakers for a more perfect finish). Our Premium No Bush epoxy is Nonyl free and uses an special curing agent is can be air shipped (shipped without restrictions). |

The least expensive FORMULATED marine epoxy available -

And NON BLUSHING too! Cheaper than even some of the '

repackaged' resins sold as marine epoxy

(which you don't want to use)

|

Epoxy Crazing Notice/Warning |

|

There are two types of Marine Epoxy Vendors: 1) discount, bulk, REPACKAGERS who simple buy drums of raw resin and raw curing agent(s) from the big chemical companies and fill plastic jugs for resale; 2) FORMULATORS take the raw epoxy chemicals add to them to enhance and improve the raw "moonshine" into a "fine whiskey". Learn more repackagers/formulators. Our Basic No Blush (tm) is a formulated non blushing epoxy by Progressive Epoxy Polymers, Inc. (homepage). that includes additions for reduced brittleness and exclusive (only we have it) bubble breakers for a more perfect looking finish. Basic No Blush is the least expensive of the formulated epoxies and considered the best marine epoxy by many ex-users of the other formulated epoxies. REPACKAGED EPOXY WARNING: Over the years I have seen and had reports of non-formulated, raw resin/cure epoxies (which are extremely hard and brittle) becoming crazed with millions of cracks (like shattered safety glass) in outdoor settings that experience big changes in temperature. Formulated epoxies all seem to be 'fixed' to allow for this expansion and contraction without cracking by making them less brittle and better able to handle internal stresses. |

|

Marine Catalog ///// Stitch n Glue ///// Epoxy Only Google Search ///// Epoxy Guru Help Site ///// Marine Boat Epoxy Etc. Links |

|

"I've been using the Basic No Blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future..." Patrick (comment with on-line order 9/4/07) ---- Order No Blush online |

.

|

|

WOW! 35% - 40% of all daily online or telephone orders are from existing customers. That's an amazing 'REPEAT CUSTOMER" number. |

|

603 - 435 - 7199 ANYTIME 24/7 FOR HELP OR ORDERS |

|

|

|

**

EMAIL / ph 603.435.7199 EST /

BUY

ONLINE ** |

|

Exterior Natural Wood Finish with No Blush Epoxy (tm) and Marine Spar Varnish |

|

This application is boat windows, but could also be done on exterior door, table, bar top |

|

|

|

"(5/2019)

Paul;

Additional Customer Notes

and Comments

|

|

Other Options: Instead of the honey thick, solvent free, Basic No Blush epoxy, the same results could be had using our solvent free, thinner Low V epoxy or even our solvent based, water thin, ESP 155 epoxy sealer (not for sale in California). Read about these product options in our Favorites Page. - These options are all available because we are a technical coatings/epoxy company and not a single product / single industry marketing company. |

|

Complete, customized, osmotic hull blister repair with Kevlar (tm) based epoxies and multiple epoxy barrier coat system options. Call to discuss your boat and purchase everything you need from a single source - plus 24/7 help and support from boating resin professionals. A Better Business Bureau Company. 603-435-7199 |

|

UNDERWATER EPOXY COATINGS |

|

|

"Protecting surfaces under the water sounds challenging, but Paul Oman reveals the secrets of third generation epoxy paints that can be used and applied underwater."

Asia/Pacific Coatings Journal April 2004 |

|

|

Read this underwater epoxy article |

|

The Marine Epoxy Everything Guide Everything from user reviews, repair examples, pricing issues and vendor evaluation tips

Basic No Blush Marine Epoxy Product Page Marine Epoxy Catalog page (multiple epoxies) Basic No Blush Marine Epoxy User Reviews / Feedback How To Evaluating Marine Epoxy brands and Vendors Marine Epoxy prices - what it really costs! Marine Epoxy amine blush - what is epoxy Blush? Boat repair examples using Marine Epoxy Dinghy Marine Epoxy boat repair case study Progressive Epoxy Polymer's marine web site Massive site of Internet boat links

|

|

Epoxy "Stab Brush" -- "Regular Brush" |

|

Use with products on this page |

|

buy separately or include with your order |

|

|

|

STAB BRUSH - 3 inch wide with 3/4 inch bristles. Most epoxies are too thick for a regular brush. Stab brushes allow you to push and move the epoxy around and 'stab' or poke it into cracks, voids, and corners |

|

REGULAR BRUSH - 2 inch wide and extra thick with synthetic bristles. Use with varnish, paints and thin epoxies. Priced for disposable use. |

|

Find Stab Brushes and Regular Brushes in our MARINE CATALOG or in our HOME/COMMERCIAL CATALOG |

|

Goto our 3rd party storefront and purchase in the MISC SECTION |

|

|

Progressive Epoxy Polymers' Paul Oman solo sailing his former Coronado 25, "Temptress " on Galveston Bay - early 1990s |

Progressive Epoxy Polymers, Inc.

** EMAIL / ph 603.435.7199 EST / BUY ONLINE **

|

|

Basic No Blush ™ |

Navigation Bar frame replacement CLICK HERE mobile friendly key site links