MARINE EPOXY

Progressive Epoxy Polymers, Inc founder PAUL OMAN

(taken at Seabrook Sailing Club - Seabrook TX -- 1990s)

Progressive Epoxy Polymers, Inc.

"The Right Epoxy Fixes Darn Near Everything!"

**

EMAIL / ph 603.435.7199 EST / BUY ONLINE **NO SALES TAX - You are shopping in TAX FREE New Hampshire

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all!

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

WoodenBoat Marketplace sponsor

"Professionals helping Professionals since 1994"

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

GOOGLE SITE SEARCH - Click here Epoxy specific site search

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

Former Sailing Instructor -- 1976 Yachting Magazine -- Jr. Article Writing contest 1st place winner --

Boat builder -- Founder: Friday Night Kayaking Club -- "Good Old Boat" magazine advertiser

- SPECIAL BULK PRICING ON MARINE EPOXIES - ANY AMOUNT OVER 15 GALLONS --

THREE MUST READ WEB PAGES

MPRICES - 2 part marine epoxy pricing issues - CLICK HERE -

MEPOXIES - comparing 2 part clear marine epoxies - CLICK HERE -

EVAL4U - how to evaluate your marine/non marine epoxy vendor - CLICK HERE -

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

|

Epoxy Crazing Notice/Warning |

|

There are two types of Marine Epoxy Vendors: 1) discount, bulk, REPACKAGERS who simple buy drums of raw resin and raw curing agent(s) from the big chemical companies and fill plastic jugs for resale; 2) FORMULATORS take the raw epoxy chemicals add to them to enhance and improve the raw "moonshine" into a "fine whiskey". Learn more repackagers/formulators. Our Basic No Blush (tm) is a formulated non blushing epoxy by Progressive Epoxy Polymers, Inc. (homepage). that includes additions for reduced brittleness and exclusive (only we have it) bubble breakers for a more perfect looking finish. Basic No Blush is the least expensive of the formulated epoxies and considered the best marine epoxy by many ex-users of the other formulated epoxies. REPACKAGED EPOXY WARNING: Over the years I have seen and had reports of non-formulated, raw resin/cure epoxies (which are extremely hard and brittle) becoming crazed with millions of cracks (like shattered safety glass) in outdoor settings that experience big changes in temperature. Formulated epoxies all seem to be 'fixed' to allow for this expansion and contraction without cracking by making them less brittle and better able to handle internal stresses. |

|

Marine Catalog ///// Stitch n Glue ///// Epoxy Only Google Search ///// Epoxy Guru Help Site ///// Marine Boat Epoxy Etc. Links |

|

"I've been using the Basic No Blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future..." Patrick (comment with on-line order 9/4/07) ---- Order No Blush online |

|

One of our marine epoxy competitors (now a mere impersonal, product line sub-division within a big industrial corporation) claims a 30% savings in time using non blushing marine epoxies. Non blushing marine epoxies do not require washing or sanding between epoxy coats or top coating with other paints. Note that we offer Basic No Blush marine epoxy with fast, slow and regular curing agents (and it also includes bubble breakers for a more perfect finish). Our Premium No Bush epoxy is Nonyl free and uses an special curing agent is can be air shipped (shipped without restrictions). |

Hello Paul:

I have been using basic no blush marine epoxy (standard cure) on my plywood boat, and I have been impressed. I work on the boat

when I have time and sometimes that means a dry 75-80 degrees, or a hot and humid 95. The epoxy seems to be very

accommodating to temperature and even an accidental improper mixing a time or two. I am ready to fillet large areas

and have been using no blush with wood flour and have been getting nice looking fillets. I need to place another

order soon...

Larry

From: Joe m. <jaaaaaaaaaaaa@yahoo.com>

To: Progressive Epoxy

Joe wrote:

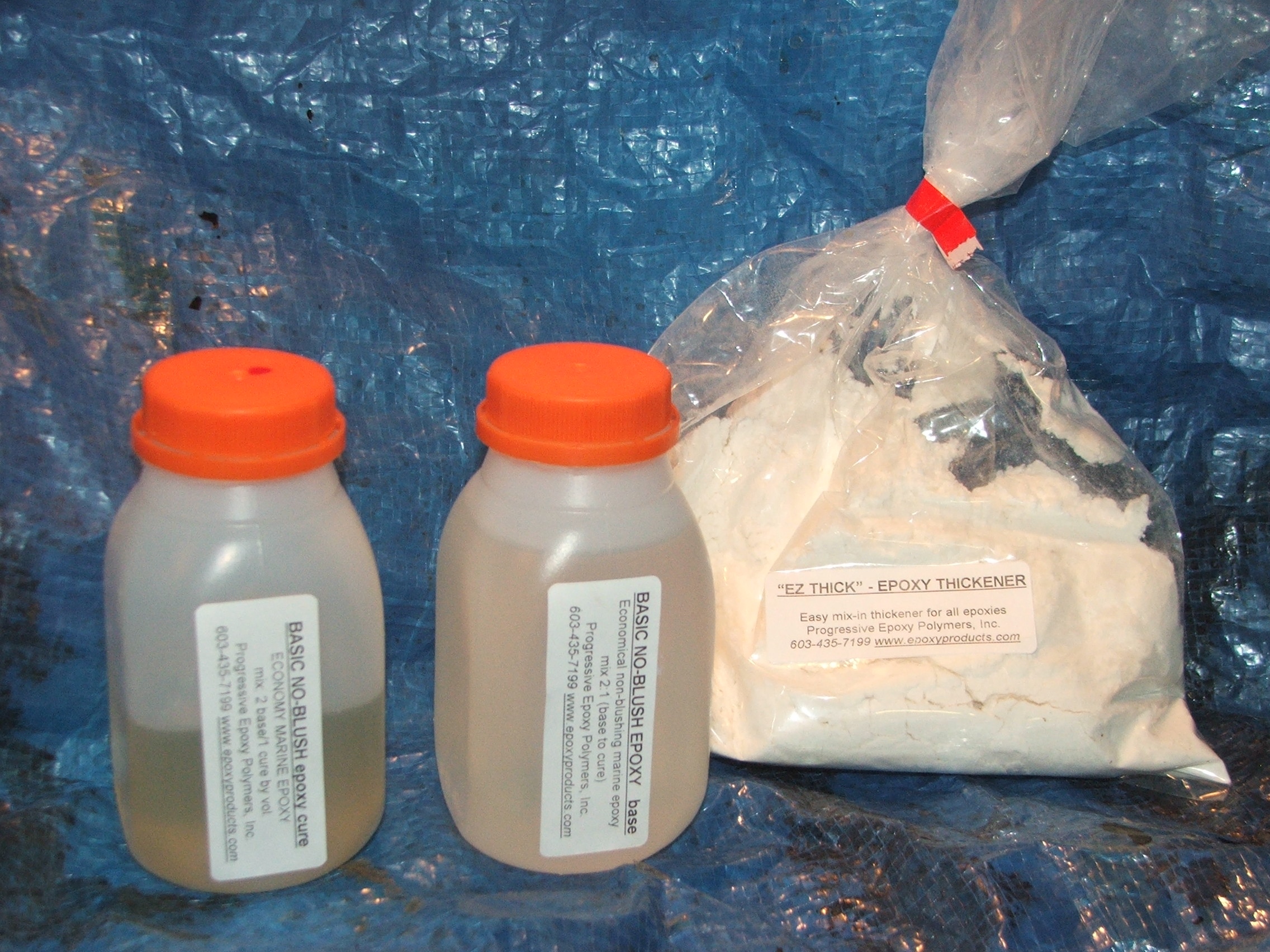

Paul, throw in 4 bags of the "e-z thick".

FYI..... I have used your marine epoxy on a lot of various applications, from thinning it for deeper penetration/sealing, to thickening for bonding multiple wood components and the stuff is great. All exterior wood gets one coat of thinned epoxy, then 2 coats full strength. then I have applied 10 coats of poly spar varnish. I have had a piece of hon. mahogany in a bucket of water for 3 months and the finish is still perfect and completely sealed. You guys are helping me restore a 35 yr. old wooden cutter, Thanks again.

Joe

July :

I'm in the process of starting a boat school in Portland, OR (http://wind-and-oar-boatschool.org/). We are

working on our first boat, which is a St Ayles skiff, with a group of 10 completely novice women doing the build.

Its the first all women build and the first on the west coast. The St Ayles Skiff is a Iain Oughtred design done

for the Scottish Fisheries Museum and now the cornerstone of the Scottish Coastal Rowing Project (http://scottishcoastalrowing.org/). Last fall

WoodenBoat Publications picked up the concept and got 5 high schools in Maine to start the boat and I am mirroring

the idea for high schools in Portland. The first youth boat will start this fall but in the mean time a group of

women approached me about building one too.

When it came time to decide about epoxies, I turned to Michael Bogoger (Dory-man) for advice. He suggested your

Basic No Blush marine epoxy and we've been extremely happy with it. The forgiving nature of the basic no-blush has been ideal for a

school situation where many people are mixing and consistency is not necessarily high. Michael has covered our

build on his blog several times and this link (http://dory-man.blogspot.com/2011/06/wind-and-oar-boat-building-school.html) is to one of his posts where you can see us using your product. His first post

about us was on the occasion of his first visit to Portland when I had him give a little seminar on epoxies.

From: Mike and Denise <fields@ozarkisp.net>

To: pauloman555@yahoo.com

Hey there,

I finally finished my boat. It is covered one end to other with y'alls epoxy. I really like your Basic No Blush marine epoxy and still no rash!

Mike Fields

VENDOR NOTE: (Mike had suffered from Epoxy Sensitivity and skin rashes from other epoxies. We don't know why he had no rash problem with our epoxy, but we're pleased that he didn't!)

I started building Puffin in January of this year, and launched her in July. I have made a few changes to better meet my needs. Puffin is a joy to sail. She is fast and very forgiving. The pic I m sending was taken in 25pmh plus wind on Greers Ferry Lake, AR. I plan to sail in the Gulf, and island hop along the Mississippi coast this summer.

W.B. wrote:

Paul-

My little company in upstate NY produces seaplane pontoons and an

occasional racing sailboat. Loved your basic no blush marine epoxy.

you should mention that when mixing large batches (1/2 gallon) it doesn't do the exotherm thing as quickly as

West.

On a warm

day with West you almost can't finish mixing before it starts to get hot hot hot.

From: David <bbbbbbb@yahoo.com>

To: pauloman555@yahoo.com

I bought a 3 gallon kit of basic no blush marine epoxy 2 last summer and have been very pleased with it. It's good stuff and

I could afford

to make learning curve type mistakes at your price. The high cost of epoxy at the local West Marine store was just

too

much and it kept me away from epoxy for too long.

I will be ordering more soon but I'm coming up short on the curing agent, I spilled some a while back. Would it

be possible

to buy an additional quart when I make my next order?

Thanks, David

VENDOR NOTE: No problem, David. We can sell you an extra quart of curing agent.

Paul,

First, a quick thank you-- I ordered your two part no-blush epoxy marine epoxy kit a few years ago for repairs on my little sunfish-type

sailboat. It was my very first epoxy experience, and your product was just terrific! Patched my holes and cracks,

and took the house paint I used perfectly...

Del S.

Subject: UV and epoxy colorings...

From: J. A.

To: <pauloman555@yahoo.com>

Excellent web site!!! I have started testing your "Basic No Blush Epoxy". Wow! Good stuff and affordable

too. I intentionally incorrectly mixed your product to test its sensitivity to mix ratio variations. Very, very

forgiving. The pot life is very consistent even with some variation in ratio and set up is consistent as well.

It also does not seem to flash as easily as other epoxies I have worked with. I got by working in the 16 oz. mixing

cups without having to pour to a wider flat bottomed container. I usually wait till an epoxy starts to flash or

just slightly heats up in the cup before I pour it into an ice cream bucket. That is of course not a summer time

practice but my shop can get down to 60 F. in the winter. But your product did not seem to heat a lot. I was even

a little nervous about it setting up but it cured like a champ! I am very happy with your Basic No Blush and I'll

be back for more.

Sincerely yours -- J.A.

using clear marine epoxy

From: Dave L.

Organization: Progressive Epoxy Polymers, Inc.

Dave wrote:

> Hi there. I have just built a small rowboat (10') using Basic No-Blush marine epoxy (fantastic resin by the

way) for

summer use here on Cape Cod. It will be stored on the beach under a cover.

> Thanks,

> Dave

Most of the 25 gals of Basic No Blush Marine Epoxy I used went into the

Xynole polyester sheathing I used instead of fiberglass. I haven't used glass much but my sense is polyester takes

about twice the epoxy. The designer's estimate was 15-20 gals total, and I think only about 5 actually went into

gluing the boat together.

stitch and glue marine epoxy construction

The thing I like most about the no blush (besides the price) is that you don't have to wash it down between coats.

Sort of obvious from the name, but I found that to be a big plus since I only had an hour or two each night to

work on the boat, so it was very convenient to be able to pick up in the middle of a filleting job for example

one night to the next without having to worry about whether the epoxy would stick to last night's work, or whether

the wood had thoroughly dried in cases where I would have otherwise had to wash or wipe it.

John

I've been using the basic no blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future...

Patrick (comment with on-line order 9/4/07)

hello:

First off, I have had very good results from your basic no blush epoxy and have built 3 wooden boats (2 kayaks

and a canoe) with your products... Bryan

Subject: Re: loved the no blush My little company in upstate NY produces seaplane pontoons and an occasional racing

sailboat. Loved your basic noblush. You should mention that when mixing large batches (1/2 gallon) it doesn't do the exotherm thing as quickly as west.

On a warm

day with west you almost can't finish mixing before it starts to get hothothot.

W.B. wrote:

paul-

From: joe m. <jaaaaaaaaaaaa@yahoo.com>

To: Progressive Epoxy

Re: 15 gallon kit

Date: Tue, 18 May 2004 16:54:01 -0400

Joe wrote:

Paul, throw in 4 bags of the "e-z thick". I think the last order I got was of the 1 gallon bags.also.

FYI..... I have used your epoxy on a lot of various applications, from thinning

it for deeper penetration/sealing, to thickening for bonding multiple wood components and the stuff is great. All

exterior wood gets one coat of thinned no blush marine epoxy, then 2 coats full strength. then i have applied 10 coats of poly

spar varnish. I have had a piece of hon. mahogany in a bucket of water for 3 months and the finish is still perfect

and completely sealed. You guys are helping me restore a 35 yr. old wooden cutter, Thanks again. Joe

The Basic Blush epoxy exceeded my expectations. Customer service and the

order process is exceptional. I'd recommend your products to others.

two part clear marine epoxy resin sampler

(email to Progressive Epoxy Polymers, Inc.): I would like to say

thank you to Paul for taking the time and chatting with me. I had various questions and he answered all of them.

His expertise in the marine world with the capabilities of his epoxy knowledge gave me a good sense of mind. I

have a 18' i/o with a delaminated inner skin on the transom his time on the phone and tricks of the trade were

a real lifesaver and saved me a lot of mental turmoil. Again:

Thank you Paul.

Thanks --

Lee

Sincerely -

Scott

Quick Buy

--

BASIC NO BLUSH (tm) MARINE EPOXY -- Now

Visit our marine epoxy products on-line catalog -

click here

BASIC NO BLUSH marine epoxy - WINTER CURE

The last two months I've been using the winter cure you sell, in several applications, all of them in unheated areas. The weather here in the Pacific Northwest is very humid and about 35 - 45 degrees. In all cases the material has set up enough to sand for repeated coats in 24 hours! In a couple instances, I've thrown patches on and even painted them the next day, because they were outside and we seldom go two days without rain this time of year. If I'd done that with the Sys. Three (blush) I've used for years, the paint would slow the cure for weeks and I'd eventually have to sand it all off because it would not stick.

I have a steady flow of old restorations in the works, so you will be hearing from me again! I've passed on some

of your data sheets to shipwright friends of mine, so hopefully they will be in touch, too. In addition to such

a reliable product, the pricing is right! Thanks again, and good luck on the kayak.

peace, Michael

VENDOR NOTE: I'm doing epoxy/fiberglass cloth boat building here in NH using the Basic No Blush with the Winter (fast) curing agent. The epoxy is stored in my basement at 50 degrees. The boat building is happening in my garage at temps in the mid 30s. The epoxy is hard the next day.

BASIC NO BLUSH marine epoxy - GLUING

One of my customers does a lot of gluing (with our epoxies) professionally. He has kindly offered to share his

methods/comments:

Hi Paul,

I don't know if I do anything all that different from anyone else while gluing teak. I do a good bit of work on

large sportfishing boats here in south Jersey. Part of the style of these boats are teak decks (1/2" thick

by 1 7/8" wide vertical grain teak) and cover boards on the gunwales. Screws and plugs are not acceptable

and the boats that have been screwed and plugged regret it when they have been sanded through in a few years. Some

of my customers have been a little concerned when I tell them the wood is "only" held by epoxy. They

have all heard of it but are not too familiar with it. Business men, not boat builders. I tell them epoxy is, first

and foremost, glue and all the cold molded boats are "only" held together with it. It just happens to

be good for other things as well. A lot of people seem to think epoxy is some sort of fiberglass resin not glue.

My routine for gluing a deck starts with grinding off the paint and leaving a very rough but fair surface. I use

40 grit discs for grinding. Obviously on new boats I dewax the surface with interlux 202 before I grind but it

probably isn't necessary. The teak itself gets hit with the grinder or sanded across the grain to roughen it up

good. The dust gets blown off and then (most important I think) I wipe the gluing side with lacquer thinner or

alcohol until no more oil comes off on the rag. This usually takes a few times and makes me wish I had a helper.

I like to set the wood, gluing side up, in the sun to heat up then wet out the wood while it is still warm. I think

I get deeper penetration into the wood this way. I don't thin the epoxy but I will warm it up to help it soak in.

I am also a nut when it comes to wetting out everything. Doesn't have to be puddles of epoxy but no dry spots.

I don't use much clamping pressure just enough to hold the wood in position. Probably nothing new here, just careful

attention to the details. I tell my customers "I can charge you the first time to do it right, but if something

fails I have to fix it for free." I can honestly say I have never had to do any warranty work.

Another interesting thing is how hot a teak deck gets. I never wear shoes in the summer (great to be me) and after

a short time in the sun these decks are too hot to stand on! I know how epoxy softens in heat but have never seen

a single plank fail to stay down. Same thing with the coverboards, though the wood is massive compared to the teak

decking. I have seen other people's work fail (job security) but always from poor prep, or improper thickener.

I fix it and pick up a customer.

Thanks Paul for a great product, great service, and that crazy web site.

Patrick, PF Custom Marine

VENDOR NOTE: The only point I can make about using epoxy to glue surfaces together is not to clamp very tightly. It is too easy to squeeze all of the epoxy out of the joint which of course means the bond will fail.

learning about epoxy resin

BASIC NO BLUSH marine epoxy - SUMMER CURE

I used it to assemble an end coaming in the cockpit. I mixed it up at 1pm and the temp in the cockpit was 98 degrees.

Outside it was 88 degrees. It had rained about 4 hours earlier and humidity was really high. All parts were epoxy

painted and then glued with a mix of epoxy

and wood flour by 1:30pm. By 2:30 the epoxy was still moveable - I could fair the thickened stuff easily with a

stick. By about 4:15 it was

non-sticky but I could still make an indentation with my fingernail. By 6pm I couldn't do that anymore - it felt

very hard.

This is in contrast to the standard cure which in these temps is only workable for between 10 and 20 minutes after mixing and is hard and non sticky within the first hour.

VENDOR NOTE: YOU CAN BLEND THE SLOW SUMMER CURE WITH THE REGULAR CURE TO ADJUST THE WORKING TIME.

BASIC NO BLUSH marine epoxy - TURNING WHITE!

From time to time we get reports of the epoxy turning white within about 12 hours of application. These reports

usually happen in the fall or late summer. I've had exactly this same thing happen on canoe seats I was coating/sealing

with clear marine epoxy (not Basic No Blush). The cause is moisture/dew/fog forming on the hours old epoxy at just

the wrong time during its cure cycle. Trapped mini water droplets look white (we've also seen the same on patio

stones coated/recoated with epoxy after it rains etc.). It is more common in the fall with lower nighttime temps

that approach or pass through the dew point. Which is why fog is usually a fall/spring event. It is easy to forget

that epoxy curing is an exothermic event and moisture can affect it. Note the Amine Blush is a waxy film forming

due to unseen moisture in the air during the epoxy cure. Many epoxy blush - the better ones, like our no-blush

have little or no blush. The white coloring seen in this example is well beyond epoxy blush and is actually 'water'

now in the epoxy. The fix is not to epoxy when temps etc. are expected to drop a good bit in the next few hours

(like in the fall!) -- i.e. outside afternoon or evening epoxy work at those critical times of the year could be

trouble. We don't see this much during the height of summer when evening temps generally stay high and well above

the dew points. All you can do is and off the epoxy and recoat.

Yes it is water - perhaps a splash or bird pee or something during the critical 'set up time' as the epoxy begins to harden.

Epoxy Putty, Thick Epoxy Resin,

"Goo", Fillers, and Thickeners

Page

|

The Marine Epoxy Everything Guide Everything from user reviews, repair examples, pricing issues and vendor evaluation tips

Basic No Blush Marine Epoxy Product Page Marine Epoxy Catalog page (multiple epoxies) Basic No Blush Marine Epoxy User Reviews / Feedback How To Evaluating Marine Epoxy brands and Vendors Marine Epoxy prices - what it really costs! Marine Epoxy amine blush - what is epoxy Blush? Boat repair examples using Marine Epoxy Dinghy Marine Epoxy boat repair case study Progressive Epoxy Polymer's marine web site Massive site of Internet boat links

|

|

Let's stay connected. It's a win-win situation. Receive our online NEWSLETTER by emailing us your name and email address. |

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option.

RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Basic No Blush - MARINE EPOXY Reviews

User comments feedback on BEST RATED clear two part marine epoxy REVIEWS