PROGRESSIVE EPOXY POLYMERS, INC.

Pittsfield NH 03263

Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Web Product CATALOGS

PROGRESSIVE EPOXY POLYMERS, INC.

Pittsfield NH 03263

Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Web Product CATALOGS

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

Information and Product Links for all things related to marine epoxies and coatings.

Informational links you will not find anywhere else on the Internet

Prepare to be overwhelmed with massive amounts of boat repair, building, coating information and links to many other marine coating related web sites - Keep viewing this page or go directly to the Links Page

CLICK HERE FOR BOAT LINKS PAGE

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

|

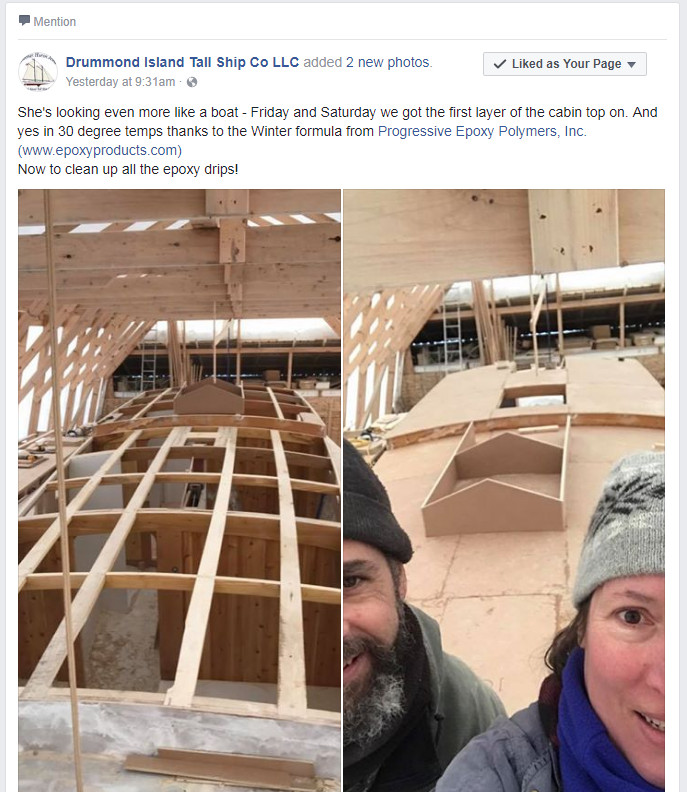

13 different marine epoxy -polyurethane coatings (www.epoxyproducts.com/ |

|

PROGRESSIVE EPOXY POLYMERS, INC also visit |

copper epoxy boat boat bottom info http://www.epoxyproducts.com/copper4u.html

|

SPONSOR AD:

Save over 50% (hundreds of dollars!)

On 2-Part Marine Topsides Paint Two part polyurethane paints are the best of user applied coatings. Automobiles and fine yachts use them We offer two outstanding products. One is a snowy white yacht coating (LPU Marine) and the other is a Clear with massive UV protection (something not often found in even the most expensive two-part polys - auto clear coat being the exception). More on 2 part polys - CLICK HERE We checked the prices for similar Awgrip brand polys at discount marine supply store WEST MARINE (Feb 2019). Their polyester polyurethane white sells for $280 per gallon. (that’s $420 for 1.5 gallons - vs. $199 for our 1.5 gal package). Use our LPU Marine polyester poly and save 53%. Our clear acrylic poly (Acrylic Poly UV Plus) vs. their clear Awlcraft 2000 clear acrylic poly (which doesn’t have the UV blockers and absorbers that our product does - a really valuable addition) - sells for $149 per gallon vs. their price of $270 per gallon. Let's talk! - 503-435-7199 - Progressive Epoxy Polymers, Inc |

Prepare to be overwhelmed with massive amounts of boat repair, building, coating information and links to many other marine coating related web sites - Keep viewing this page or go directly to the Links Page

CLICK HERE FOR BOAT LINKS PAGE

"The Right Epoxy fixes Everything!"

Visit our Subject / Catalog contents PAGE

Site sponsor - buy epoxy floor paint web site and domain