PROGRESSIVE EPOXY POLYMERS, INC.

GOOGLE SITE SEARCH - Click here

|

WHO ARE WE? Make sure you are purchasing your epoxies from a real epoxy company and not a bulk repackaging company Watch our short 2-minute company presentation. Progressive Epoxy Polymers video |

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

PRIMARY STORE LINK --- TOP SELLING PRODUCTS --- EPOXY GURU HELP SITE --- ALUTHANE MCU PAINT --- BASIC NO BLUSH (MARINE AND STONE EPOXY) --- BUY NO BLUSH

You won't learn if you don't ask! We share information 24/7 and earn your business!

| HOT SPOTS: | shippingContainers | swimPool | bartops | cellarLeaks | dataSheet |

| barrierCoats | pebbleDeck | floors | boats | rot | HELP/INDEX |

You're talking with: Paul Oman, MS, MBA -- Member since 1994: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings) -- Technical Help - not sales talk! goto store

|

If your "HELP" person can't explain nonyl-phenol, cyclo-aliphatic epoxies, epoxy adducts, MCU urethanes or LPU polyurethanes, they're salespeople and not coating professionals. If your "SUPPORT" person won't return your call on a Sunday afternoon, they're not really interested in you. At Progressive Epoxy Polymers/EpoxyProducts.com we are your Help and Support Professionals. Call : 603 - 435 7199 |

"You provide outstanding products, and Fantastic Support. Thank You." Brian S. (call 603 435 7199 anytime)

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

UNDERWATER EPOXY REPAIR

A Case Study Using Progressive Epoxy Polymer's Underwater Epoxies

Underwater epoxy for Emergency hull repair - sinking yacht Case Study

ABSOLUTE BEST SOURCE for epoxy information, options, USA made products, 24/7/365 help, and support

(EMAIL 603 435 7199)

|

24/7 free support help and order line 603-435-7199 No sales tax (New Hampshire Location) |

Emergency Boat Repair Epoxy Resin - Underwater Hull

Rescue

Underwater epoxy for Emergency hull repair - sinking yacht Case Study

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings) - BoatUS (since 1980)

WoodenBoat Marketplace sponsor: www.woodenboat.com/business/category/adhesivescoatings/

"Professionals helping Professionals since 1994"

CALL 603-435-7199 (or email). We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

|

PAGE AND SITE NAVIGATION |

|||||||||||||||||

Marine Epoxy Links Page ====> Part #2 Sub-Page ====> This 'Linked To' underwater epoxy repair Sub-Page

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

MEMBER: Internet Epoxy Confederation (IEC - CLICK HERE TO VISIT) -- "Where Professionalism Still Matters"

We've been selling epoxy - marine epoxy (boat building - wood / fiberglass repair) industrial coatings - garage paint - underwater epoxies - thick putties - tabletop resins and supplies since the early 1990's |

| marine BARRIER COAT epoxy... | hull BLISTER REPAIR... | MARINE EPOXY... |

|

|

Yes you can apply some of our special epoxies underwater. Fix your boat, your pool, your basement - and more! CLICK HERE |

|

|

UNDERWATER EPOXY COATINGS |

|

|

"Protecting surfaces under the water sounds challenging, but Paul Oman reveals the secrets of third generation epoxy paints that can be used and applied underwater."

Asia/Pacific Coatings Journal April 2004 |

|

|

Read this underwater epoxy article |

|

WE'RE THE BEST SOURCE FOR ALL BOATING RELATED EPOXIES AND COATING! HERE'S WHY: No matter if your boat repair/building project is sitting in a 39 degree barn or sunk in 10 feet of water in the local harbor, our epoxies can save your day. We have Kevlar (tm) reinforced epoxies, marine non-blushing epoxies with bubble breaker additives (no one else has that!), two part polys in white or clear, and old fashion spar varnish. The clear has massive amounts of UV blockers. Need an epoxy barrier coat or an epoxy sealer/primer for that old weathered fiberglass hull? Does you hull have blisters? Need a thickened epoxy or DIY epoxy thickeners? Does the pontoon boat leak? Need to repair a spongy, rotting deck core? We can do all of that and also save your sinking or sunk boat AND help you build that stitch and glue kayak or 72 foot schooner (they used 200 gallons of our epoxy!). PROGRESSIVE EPOXY POLYMERS INC. (marine catalog) or just call us 603 - 435 -7199 - available nights and weekends. Email anytime. - TOP FAVORITE EPOXIES --- WEB BOAT REPAIR LINKS --- BOAT EYE CANDY! |

A case study shows why you should

carry underwater epoxy on your boat at all times - Even if you only sink at your local boat ramp

It can do "save the day" repairs, even if you are not sinking

(if you don't believe us, buy the book)

The difference between your best boating day and your worst boating day could be having some underwater epoxy on hand

|

Order WET DRY 700 UNDERWATER EPOXY PUTTY by calling 603-435-7199 anytime or order online using this link: EPOXY NOW |

Available at Barnes and Noble and Amazon

Email Message

Subject: Progressive Epoxies

Date: Sun, 17 Aug. 2003 23:36:47 -0770 (PDT)

From: Joy Sxxxx <bansheeboat@xxxxxxx.xxx>

To: pauloman@pauloman.com

Paul:

Remember me? Joy Smith and her sunk boat in Papua New Guinea around Christmas time last year??

By the time I finally left my boat and got off the island, got to civilization and then found your website, in my desperate search for an air-shippable underwater epoxy, we had been marooned on remote Hermit Is., PNG for two months. Banshee sank on October 21, 2002, in three minutes, after hitting a coral head and was completely underwater for three days. There was a 6 ft. crack through the hull and a punched in hole about a foot in diameter. The damage was massive.

Leslie patched the hull with old Z-Spar Splash Zone and a piece of wood a villager

shaped with an axe. We kedged it off the reef, winched it upright, and then the villagers built an underwater cradle

of lashed together logs to support Banshee. We bailed with buckets during a very low tide at night. She floated.

The inside of the boat was trashed, the electric/electronics destroyed, the engine unusable, lots of things stolen,

and diesel oil, sandy sea water and ocean bottom rubble and mold covered everything. But the sailing rig survived.

However, it soon became apparent that the old Z-Spar patch would never hold for a 300 mile open sea voyage to Madang,

PNG and dry dock for hull repair. As I told you when I wrote in December, the hull was steadily leaking, and we

knew the temporary repair would not last much longer.

I was desperate to save my boat that has been my life for 32 years.

I bought your underwater epoxy, and you shipped it to Manus Is., PNG. I picked it up and returned to the remote

island of Hermit-what a name!! Almost didn't make it back as a storm came up while we were in the open 26 ft. boat

making it back to the island. 36 hrs in an open boat with heavy seas with local bush people and me! BUT I HAD THE

EPOXY AND KNEW WE WOULD NOW SAIL BANSHEE OFF HERMIT.

The whole saga is a very very long story of an incredible three month ordeal for two

women alone. I got back to Hermit in mid January, and Les and I applied your stuff according to your directions.

We patched the hull inside and out as you said. By then, the leakage from the 10 year old Z-Spar Splash Zone was

getting worse. However, your stuff stopped all the leaks.

After 3 weeks of working on the boat, we left Hermit for the voyage to Madang, PNG. Sailing the 300 miles with

no engine, no electronics, no autopilot, no functioning life raft, and very little food or water. There were very

high winds and rough seas and then dead calms, and we only had wind and sails alone to get us across that ocean.

YOUR REPAIR STUFF HELD!! The hull had a fierce pounding-but no leaks. WE MADE IT!! We were towed in at the entrance

to Madang Harbor and collapsed in exhaustion.

If we had not had your epoxy - our boat which is our life would still be under water at Hermit. We owe a debt of

gratitude to you. The boat was put up in a primitive dry dock, and we literally cut out the repaired hull with

a diamond tipped saw. Your stuff eats sanding grinders! We are good at epoxy repair of hulls-thank goodness, because

no one here knew anything. Before we had properly repaired big holes where thru-hulls had been removed by building

up larger and larger layers of mat and roving with epoxy resin. Leslie is very good at that-having worked in a

fiberglass repair shop. This was just a bigger job.

Ghastly work. We have pictures of the repair and the 6 ft. long crack and hole in the hull.

We are now safely sitting in an anchorage in Madang rebuilding, and rewiring with our very limited funds. We plan

to leave Madang for Guam and employment in December. The story became such an incredible one about doing the impossible

that some publishers in the states are interested. I am writing a book about the whole ordeal. There will be an

article in Sailing magazine. An article in the online magazine of Andrew Corp.. makers of our GPS antenna, has

gone to press. Now, ACR Electronics, maker of our EPIRB that notified authorities of our disaster, is interested

in an online article.

All because you were kind, took time to help me, and had the right stuff. I should have written many times before,

but work on the boat kept interrupting me. Its been non-stop since we got in. You and your company will have star

billing in any written piece that comes from me. Also, I think its important for sailors to feel that if the unspoken

fear that we all have - holing and sinking - actually happens, one has options other than just walking away as

so many told me to do. Two women did this - they can to! I am 61 and Leslie is 44. We did not walk away!

I feel that any person taking a boat to sea anywhere, anytime, should carry your product aboard and know how to

apply it. If I can assist you in distributing or advertising your product, I am more than happy to do so.

Very thankfully,

Joy S. and Leslie B.,

US Yacht Banshee

Madang, Papua New Guinea

Since the 2002/2003 sinking and repair the Wet Dry 700 epoxy can no longer be shipped outside the USA.

The the thick but rollable Corro Coat FC 2100A can still be air shipped and thickeners can be added to make it more

of a paste. The Quick Fix 2300 has limited structural adhesion and is being phased out.

The Wet Dry 700 and the Corro Coat FC 2100A remain top selling products both for underwater and dry surface repairs and can be found in or Top selling/Favorites epoxy catalog.

-- I'm proud our products and customer service saved the day - and it still does over a decade later -- Paul Oman

call anytime to talk about your project 603 -435-7199

|

"JUST WANTED TO LET YOU KNOW I HAVE COMPLETED MY REBUILD ON THE 1975 SKI NAUTIQUE. I AM MORE THAN IMPRESSED WITH YOUR PRODUCTS AND EVEN MORE SO WITH YOUR CUSTOMER SERVICE. A + COMPANY." - Bob 10/14 |

The Wet Dry 700 epoxy putty is a product that many people buy for a specific project (sunken boat, rot repair, wet surface or underwater patching, gluing things together etc.) and then come back and purchase more, "just to have around". It cannot be shipped by air and cannot be shipped outside of the lower 48 states. Order it BEFORE you need it! As the owner of the sunken yacht proclaim, - DON'T GO OFFSHORE WITHOUT IT!

|

Why Wet Dry 700 epoxy is the BEST in its class: 1. An apply underwater superior resin system 2) cycloaliphatic epoxy system 3) Kevlar (tm) reinforced epoxy 4) not too thick, not too thin, patch and repair gel (like cake icing) 5) strong user support / feedback 6) 24/7 support other common applications: hull putty, adhesive, seal electrical connections, rot repair --find in Favorites Catalog

|

| THIS PRODUCT | xx | EMAIL US | xx | |

| air shippable | cycloaliphatic system | xx | ||

| no nonyl phenol | epoxy adduct system | |||

| multi curing agents | bulk pricing | xx | ||

| solvent free | xx | no Calif. sales | ||

| 2 part epoxy | xx | 2 part poly | ||

| apply underwater | xx | bubble breakers | ||

| favorite(s) product list | xx | data sheets | xx | |

| PACKING - jugs/bottles | PACKING - cans | xx | ||

| find in non marine cat | xx | find in marine catalog | xx | |

| PRICES/ind/commercial | xx | PRICES/marine section | xx | |

| BUY online | xx | BUY online | xx | |

| home page | xx | contact page | xx |

We really appreciate you visiting PROGRESSIVE EPOXY POLYMERS, INC. and our web site: EPOXYPRODUCTS.COM. Take advantage of the CONTACT links on this page to ask questions about our products and/or your projects. You can stay in touch with us via our NEWSLETTER (link on our contact page) which is emailed every 6-8 weeks.

Emergency Boat Repair Epoxy Resin

- Underwater Hull Rescue

Underwater epoxy for Emergency hull repair - sinking yacht Case Study

|

|

WOW! 35% - 40% of all daily online or telephone orders are from existing customers. That's an amazing 'REPEAT CUSTOMER" number. |

|

603 - 435 - 7199 ANYTIME 24/7 FOR HELP OR ORDERS |

|

|

|

|

|

|

BOAT BUILDING SUPPLIES AND INFO |

| Non Blushing Marine Epoxy | Marine Epoxies (find in catalog) |

| Epoxy Fillers / Thickeners | Fiberglass Cloth |

| "Stitch and Glue" building | Underwater Epoxy Repairs |

| Varnish Info | Varnish (find in catalog) |

| Dinghy Repair | Massive Boat Links Site |

| Email Us |

Call 603-435-7199 help/orders |

Products/Links:

Find Corro Coat FC 2100 in our

marine catalog -- in our

industrial catalog

Note: one underwater repair trick is to soak sponge/foam rubber with this epoxy and then jam (caulk) underwater seams, cracks, holes, etc. with the epoxy soaked foam. It will swell to form a tight seal and become rock hard.

|

Why Corro Coat FC 2100A epoxy is the BEST in its class: 1. Gap filling Kevar (tm) based epoxy paint 2) can be applied underwater 3) special high end curing agents allow shipping by air 4) no nonyl phenol 5) cycloaliphatic formulation 6) no odor or solvents 7) strong user support / feedback 8) 24/7 support --- picture 'gray applesauce' in texture and thickness --- other common applications: basement leak repair, tank and pit liner -find in Favorites Catalog |

| THIS PRODUCT | xx | EMAIL US | xx | |

| air shippable | xx | cycloaliphatic system | xx | |

| no nonyl phenol | xx | epoxy adduct system | ||

| multi curing agents | xx | bulk pricing | xx | |

| solvent free | xx | no calif sales | ||

| 2 part epoxy | xx | 2 part poly | ||

| apply underwater | xx | bubble breakers | ||

| favorite(s) product list | xx | data sheets | xx | |

| PACKING - jugs/bottles | PACKING - cans | xx | ||

| find in non marine cat | xx | find in marine catalog | xx | |

| PRICES/ind/commercial | xx | PRICES/marine section | xx | |

| BUY online | xx | BUY online | xx | |

| home page | xx | contact page | xx |

(user feedback) "I had been fighting a hydro-static leak between my floor and foundation on the south wall of our basement that has a terrace garden on the exterior for about the last 5 or 6 years. I have applied several coats of concrete patch that were very ineffective.

When I saw the ad on the internet for this product I thought that it might work, so I emailed Paul Oman and we exchanged thoughts and ideas. I purchased the product to try it out. Early in April I applied one coat and sat back during the rainy season to see what would happen. We had record rains in St. Louis this April and so-far-so-good; no leaks. I am convinced that it is a good product".

Find this epoxy in our Best Selling - fix anything Catalog

Products/Links:

Find WET/DRY 700 in our marine catalog -- in our industrial catalog. This underwater epoxy boat repair product can no longer be shipped by air. - THIS THE OUR #1 - BEST - EMERGENCY REPAIR EPOXY

Jeff (1/2013) "I cannot believe how incredible this Wet Dry 700 is. It's revolutionary. The original repair to my storm shelter would have lasted years if the shelter would just stop shifting around in the ground. DON'T STOP SELLING THIS STUFF."

"The Wet Dry 700 epoxy paste worked great for patching for the rotted dingy transom. I cut out the rot, fitted new oak pieces, and patched with the Wet Dry 700 epoxy. Easy as pie." -- John 1/15

"This product saved my boat a year ago (underwater leak) and I used it for several other projects. Time for more. Thanks." -- Gary 8/2010

other common applications: hull putty, adhesive, seal electrical connections, rot repair --

find in Favorites Catalog

Find this epoxy in our Best Selling - fix anything Catalog

|

WET DRY 700 (tm) - kevlar (tm) / feldspar/ceramic industrial grade epoxy paste. Cures underwater or on dry surfaces. If you only kept one epoxy putty repair product on your boat, workshop, or tool box, this would be it. This off-white epoxy (turns yellow over time) can be applied underwater. It has saved sinking boats, leaking swimming pools, repaired rotting window sills, and bonded wood to wood, wood to cement walls etc. Wall mud or cake icing thick. Not be be confused with our thick light blue or white Water Gard 300 epoxy paint which can also be applied underwater (generally pool repairs or marine barrier coats) or our thick, gray, kevlar (tm) reinforced epoxy underwater paint, Corro Coat fc2100A. CLICK HERE FOR MORE INFO on all three of these industrial epoxies. Jeff (1/2013) I cannot believe how incredible this Wet Dry 700 is. It's revolutionary. The original repair to my storm shelter would have lasted years if the shelter would just stop shifting around in the ground. DON'T STOP SELLING THIS STUFF. (10/2013) Comments: Returning - Underwater boat repair - My third or fourth order and am still quite pleased with the result. It has many uses above and below the water line.

|

Note: we also sell the Splash Zone product mentioned above, no longer a Z Spar product.

ONE PAGE SUMMARY OF ALL PRODUCTS - MARINE RELATED

ONE PAGE SUMMARY OF ALL PRODUCTS - HOME - COMMERCIAL - INDUSTRIAL

|

Visit us for EPOXY PRODUCTS and EPOXY INFORMATION |

|||||

www.EpoxyProducts.com Progressive Epoxy Polymers, Inc. (since 1994)

marine resins - epoxy paints - bar top resins - floor epoxy - resin repair products - underwater epoxies |

|||||

|

Stay for the pictures Over 500 eye-catching pictures scattered across 200 epoxy pages on this major internet site homepage -- contact page --- boat links --- floor links --- bar top epoxy |

|

Epoxy Only Web Google Search |

|

|

#1) Google Everything Epoxy Searches #2) Google Marine Epoxies Searches

#3)Google

Floor Epoxy Searches |

|

View our Progressive Epoxy Products, Inc. |

|

Links for UNDERWATER EPOXY Application of "underwater" epoxy paint and putty for repair and as an adhesive. Underwater swimming pool epoxy paint and repairs - Wet surface painting. Yes, you can apply some special epoxy paint/putty coatings UNDERWATER

1) application of underwater epoxy paint (photograph) ----- uwpaint.html 2) (this page) underwater repair epoxy saves sinking yacht ----- cs_boat.html 3) history of underwater paint putty epoxy ----- uwhistory.html 4) description / BUY LINKS for underwater epoxy paint putty adhesive ----- under4u.html 5) epoxy and non epoxies that can be used (not applied) underwater ----- immerse.html

Contact Page (phone or email us) Links to online storefront for buying UNDERWATER EPOXY Splash Zone A-788 -- Wet Dry 700 -- Corro Coat fc2100A -- Water Gard 300 |

PROBLEMS WITH UNDERWATER EPOXY BONDING - A WARNING

BOAT LINKS - find pages related to your issue CLICK HERE --- EPOXY RELATED BOAT REPAIR LINKS

BOATS - GOTO our boat home page and catalog pages

(distributor prices for all on our two part BASIC NO BLUSH ™ marine epoxy resin - DETAILS epoxy prices)

|

Complete, customized, osmotic hull blister repair with Kevlar (tm) based epoxies and multiple epoxy barrier coat system options. Call to discuss your boat and purchase everything you need from a single source - plus 24/7 help and support from boating resin professionals. A Better Business Bureau Company. 603-435-7199 |

|

The Marine Epoxy Everything Guide Everything from user reviews, repair examples, pricing issues and vendor evaluation tips

Basic No Blush Marine Epoxy Product Page Marine Epoxy Catalog page (multiple epoxies) Basic No Blush Marine Epoxy User Reviews / Feedback How To Evaluating Marine Epoxy brands and Vendors Marine Epoxy prices - what it really costs! Marine Epoxy amine blush - what is epoxy Blush? Boat repair examples using Marine Epoxy Dinghy Marine Epoxy boat repair case study Progressive Epoxy Polymer's marine web site Massive site of Internet boat links

|

"Epoxy Guru"

Free Epoxy help and

information web site

Free Technical Support

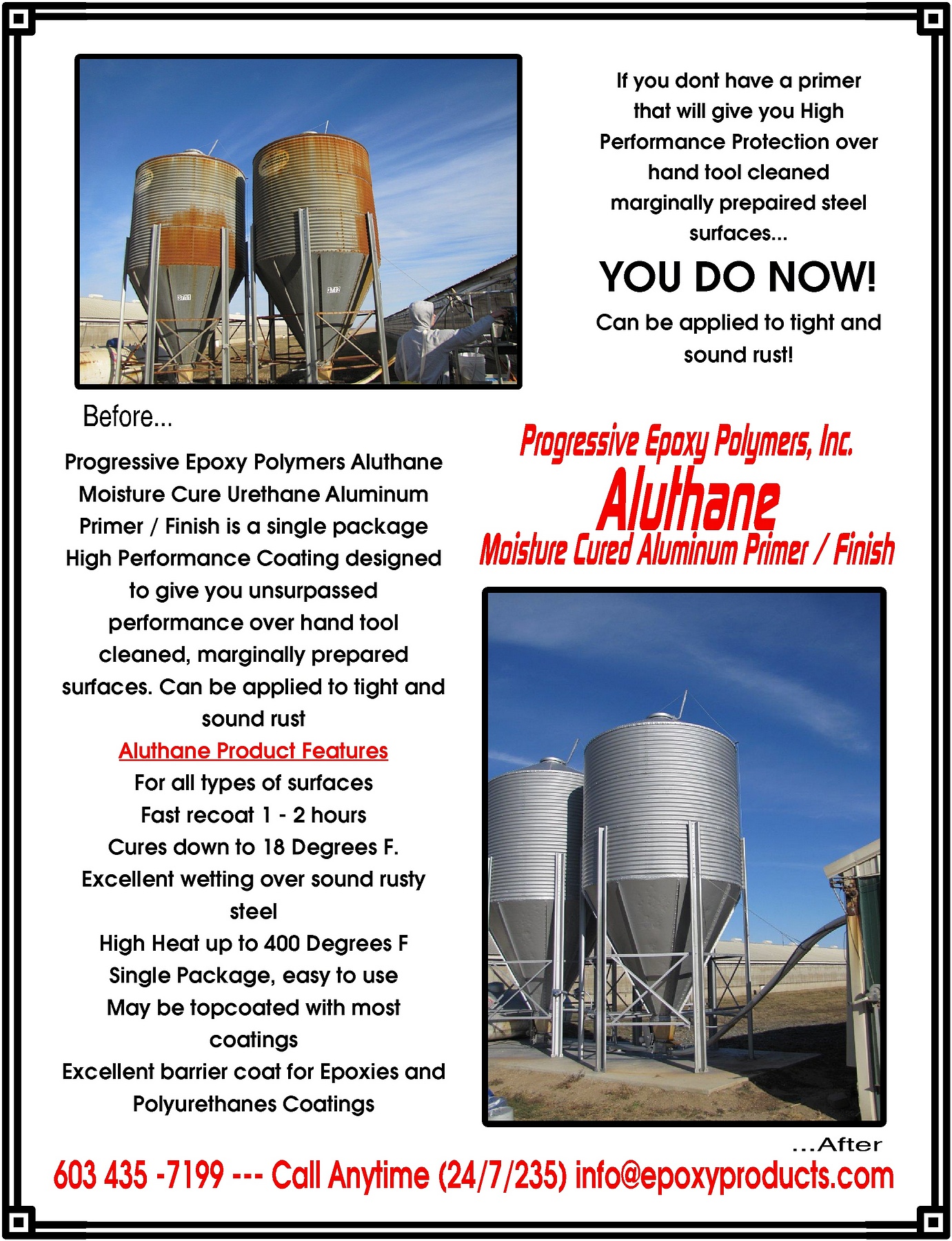

ALUTHANE MCU - Moisture Cured Urethanes for Home - Marine - Industrial

(steel, fiberglass, wood, aluminum, concrete)

|

ALUTHANE (tm) ALUMINUM PAINT moisture cured urethane |

stops leaks too! |

|

Before Pictures |

After Pictures |

|

|

|

|

|

|

|

|

|

|

(customer review) "Many aircraft paint systems use finely powdered aluminum as a blocker, and this is a proven technology. The paint must stick well to dacron, retain good flexibility for many years, and generally be a tough coating. It should seal the fabric, reducing any airflow (air leakage) to a minimum. In my experience Aluthane meets these requirements.

Aluthane wets out on dacron beautifully. It penetrates and seals, too. I made up a 18" x 20" test panel and stretched 2.7 oz aviation fabric at 300F.

I had Aluthane on a dacron outdoor test panel for five years. It was still in good condition after five years, and continued to adhere well. I flew an airplane for four years with the Aluthane topcoated with Polyfiber Bahama Blue. Both the Aluthane and the topcoat remained flexible.

Aluthane also appears to stick like crazy to both aluminum and fiberglass!" email - 10/14

"Hi Paul,-- We have been using the Aluthane product for 6 years now and it has been a blessing for our business." (11/14)

| Order this product by calling 603-435-7199 anytime or order online using this link to our Primary Web Store: EPOXYPRODUCTS |

Tom wrote (10/2008):

Thanks Paul; here are a few comments on the Aluthane.

I was looking for a product to use on the 4" steel pilings on a newly constructed boat house. I wanted to

extend the life of the piles and the overall structure since the boathouse cost roughly $50K to build. Aluthane

was recommended. At the time, the water was down around three feet from normal pool so I was able to paint roughly

4 feet of the piling that was exposed. For prep, I used a simple paint scraper to smooth off the rough, loose rust

and then a wire brush. I did not put a lot of effort into preparation. Total prep time per piling was no more than

3-5 minutes. I used a 3" roller and rolled the Aluthane on. Again, very simple and quick.

Hi Paul,

I was working on the boat today and couldn't help but notice how sharp my aluminum hardtop (still) looks after

a very harsh summer of hard work on the salty ocean and a long New England winter exposed to the elements.

I remember the day I finished welding my hardtop and sat baffled as to how to finish it. You see, the hardtop frame

was comprised of a half cut-up Mako tower (anodized aluminum) and scrap 6061 aluminum, all TIG welded together.

With little to no prep, aside from a light sanding and a wash with alcohol, I was able to brush on (stippling)

two coats of Aluthane in a day and have the boat launched a week later. Since then, the frame has seen rope chaffing,

scrapes, climbing crew with abrasive sandy shoes, and harsh sun and seawater. The finish has never worn through

and shows no signs of damage.

It has held up marvelously. So well in fact, I go out of my way to find things to paint with Aluthane. So far,

I've painted my engines heat exchanger, primer my manifolds and risers, painted parts of my galvanized trailer

including the wheels, and various mixed metal hardware on my boat.

I've recommended this product to others looking for a tough coating that can take a beating. A little goes a long

way with Aluthane and it is almost funny how easily it goes on, rolled or brushed. One caveat, brushing will show

brush marks so I usually stipple the surface with a brush with its bristles cut way back (or roll it on). Continuous

mixing is key, too. It isn't glossy which is nice in some cases.

Paul 4/09

From comment section of 6/2010 online order for 1 gallon of Aluthane: "Returning (vendor note - a past customer). Spiral stairs near ocean. Wonderful coating that resists corrosion."

John (2/16/2012 email): A Wonderful Product!! Love Using It For A Little Of Everything!!! Proud To Buy American Products!!

My first experience w/ Aluthane was on my 1966 Starcraft boat....then with the left over quart I did the main door on my garage.....after that....I still had enough to apply a coat onto my rear bumper of my F250. This time around.... I used 1 quart again on: The in and outside panel of a retired U-Haul Truck (33 5/8 in. x 6 1/2 ft).....all the interior wall panels of the box truck (it's a 14 ft. box with grandmas attic)....and a 80# saddle propane tank. It's been an average of 28* up here for a high and it applied beautifully.....drying time is slower (I expected this)....but it coated just as smoothly as if it was 75* and sunny.

I totally agree.....b4 I crack a 1 quart container....I make sure I have enough things to coat so I don't hafta waste it in the garbage. I've been telling as many people as I can about Aluthane (and about you guys and galls).....telling them what I've been using it on and how nice it looks...and how smoothly it helped water proof my 46 year old boat and with a teeny bit of help from Marine Goop. My boat flows so smoothly through the water.....you would have never guessed that it leaked pretty good b4 the Aluthane and Goop.

I just hope and pray that this Economy and World Govt. doesn't shut you guys and gals down. That will be a VERY VERY SAD DAY for all the DIY's and commercial and industrial accounts you deal with on a regular basis.

Keep up the WONDERFUL WORK!!! Love the product so much!!! OMG.....I wanna coat everything exterior with it.... LOL. But seriously... when I get a chance.... I will be using the 1 Gallon Aluthane to do both of my porches. Have a great day and year. And blessed be us all.

John

Inside Our Marine Catalog:

Section One TWO PART MARINE EPOXIES- CLEAR EPOXIES

basic no blush epoxy, premium no blush epoxy, esp 155 epoxy, low v epoxy

Section Two FILLERS THICKENERS ADDITIVES

fumed silica; microsphere/balloons; poly fibers; graphite, wood flour; EZ thick; rock flour

Section Three THICKENED EPOXIES - EPOXY PUTTIES, ETC.

wet/dry 700; splash zone; epoxy cream; splash zone a-788

Section Four TWO PART EPOXY PAINTS (barrier coats)

corro coat FC 2100; water gard 300; CM 15; liqua tile 11 72 potable water; rough coat; water prime

Section Five URETHANES AND NON-EPOXY COATINGS Aluthane (aluminum coating); LPU Marine; india spar varnish; acrylic poly uv plus, polyester poly

Section Six NON-SKID DECK COATINGS

walnut shell,; s15

Section Seven MARINE REPAIR PRODUCTS

pipe wrap; fiberglass tape (cloth); Capt. Tolley's Creeping Crack Cure

Section Eight MISC. MARINE PRODUCTS

short nap rollers; TA 661 (solvent free epoxy clean-up); 1 inch foam brushes; 2 inch bristle brushes; tongue depressors

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

GOOGLE SITE SEARCH - Click here Epoxy specific site search

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

Click here - Dozens of boat repair info links across the internet. - (everything is here!)

THREE MUST READ WEB PAGES

MPRICES - 2 part marine epoxy pricing issues - CLICK HERE -

MEPOXIES - comparing 2 part clear marine epoxies - CLICK HERE - (you are here already!)

EVAL4U - how to evaluate your marine/non marine epoxy vendor - CLICK HERE -

|

|

Most Popular & Visited pages at: Epoxyproducts.com (see below) Check Us Out! |

storefronts, phone, text, email links |

|

Also check out these pages ==> |

help and info |

trusted epoxy sites |

|

|

|

||

|

site master |

protagonist |

ground zero |

|

|

Basic No Blush ™ #1 rated, formulated, clear marine epoxy. Sold to the public at distributor prices. --Click Here-- . |

| Help Page - Catalog Page Links |