Progressive Epoxy Polymers, Inc.

"Your Friend in the Epoxy Business"

Pittsfield, NH 03263

** EMAIL / ph 603.435.7199 EST / BUY ONLINE **

Nothing but Quality Products at Good Prices, Great Customer Service, and Lots and Lots of Helpful Information

and NO SALES TAX - You are shopping in TAX FREE New Hampshire

.

The only Kevlar (tm) based epoxy blister repair system

Boat Blister Repairs - Fiberglass

hull Epoxy Repair - Boat Pox

DIY fixes for repair of fiberglass boat gel coat hull blisters -- MARINE EPOXY

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

Boat U.S. member since 1980

Former Sailing Instructor -- 1976 Yachting Magazine -- Jr. Article Writing contest 1st place winner -- Boat builder -- Founder: Friday Night Kayaking Club

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!).

\

DIY fixes for repair of fiberglass boat gel coat hull blisters (marine epoxy)

Fiberglass boat hulls are subject to the formation of blisters within the fiberglass hull layers below the waterline. These blisters vary in size, but all represent a damage site to your hull. The blisters are a result of moisture being absorbed into the fiberglass, probably due to sites of less then perfectly cured fiberglass polyester resins. A smelly, watery fluid fills the blisters and may actually squirt out when the blister is punctured.

Repair and prevention are topics of much debate. Repairs range from the complex to the simple. One end of the spectrum consists of sealing the boat in an airtight bag and using commercial dehumidifiers to suck out all moisture in the hull followed by completely cutting out the blister and repairing as one would repair a hole in the hull. Many people will let a hull dry out for weeks after lancing and opening a blister. On the other end of the spectrum, some people will do little more than lance a blister and almost immediately putty over it.

Prevention currently consists of applying several thin barrier coats of epoxy to the hull. Epoxies are less porous than the polyester resins used in production fiberglass boats. (see our products page for barrier coat epoxies).

Our Solution - The Blis-Coat Repair System:

Using various space-age, water-displacing, proprietary epoxies, Progressive Products, Inc., distributors of marine and industrial epoxy products has developed a system to both treat and help prevent blisters. The system is quick and easy and allows users to also include more extensive repair procedures should they deem it necessary. We believe our system offers a suitable solution to most blister situations. Ultimately however, it is the boat owner that must decide how extensively to repair blister damage.

We believe our system is a quick, adequate method for dealing with hull blisters and one that even inexperienced and impatient boat owners can easily master.

The Blis-Coat System consists of the following steps:

1) Open up the blister and remove the mostly heavily damaged surrounding fiberglass using a metal file bit (rasp bit) with an electric drill. As the blisters are generally filled with liquid expect a mushy mass of fiberglass dust to fill the area. Suitable protection should be taken to shield exposed skin, mouth, eyes, throat from the resulting fiberglass particles that this drilling/grinding will release.

Rather than completely grinding out ALL the weakened fiberglass (no reason why you cannot do this) we're stabilizing the remaining weakened fiberglass with our water displacing epoxies. These epoxies can literally be applied underwater. They ‘push' the water away — the path of least resistance is the open blister. Even if left within the hull the water mini-droplet (without the unreacted resins) shouldn't cause a blister or create any problem.

2) Thoroughly flush the blisters with water either from a water-blaster unit or garden hose. The object is to remove any residual chemical contaminants as well as fiberglass and resin dust.

3) You may wish to repeat the grinding and washing step above until you are personally satisfied with how well you have opened each blister and removed the worst of the fiberglass damage.

4) Let the blisters dry so that all obvious loose droplets and signs of moisture have evaporated.

5) Using our thin water-displacing, two-part epoxy resin (Low V) and a paint brush vigorously rub/brush/push/swab resin into each opened blister. Work quickly, pot life is about 20 minutes. This special epoxy will displace any trapped water (literally bonding and curing underwater if necessary) and penetrate any loose or open fiberglass around the blister. Let cure overnight or longer.

6) Patch and fill in the blisters, as well as any other necessary boat bottom repairs, with our WET DRY 700 epoxy putty. Fill the blisters using a putty knife or plastic edger. Perform any final filling/sanding/smoothing over the blisters in preparation for applying anti-fouling paint or optional barrier coat (see our products page for barrier coat epoxies).

In A Nutshell (summary):

1) grind open and clean blister of chemicals and crud with a hose

2) seal with Low V epoxy to seal and firm up blister (a solvent free thin epoxy that will firm up the damaged area - you can even use LOW V epoxy underwater - often used to firm up spongy boat deck cores weakened with rot and water)

3) patch and fill with Wet Dry 700 Kevlar (tm) filled epoxy putty (Wet Dry 700 saves sinking boat) This apply underwater epoxy paste can be used with or without fiberglass cloth. In an emergency it could save your boat (or your family!) The kevlar (tm) filler turns the Wet Dry 700 into a serious structural repair resin system.

|

Why Wet Dry 700 epoxy is the BEST in its class: 1. An apply underwater superior resin system 2) cycloaliphatic epoxy system 3) Kevlar (tm) reinforced epoxy 4) not too thick, not too thin, patch and repair gel (like cake icing) 5) strong user support / feedback 6) 24/7 support |

Quick access to the combined data - technical

document for LOW V EPOXY

can be found at: Click Here - greatthings4u.com

Quick access to the combined data - technical

document for WET DRY 700 EPOXY

can be found at: Click Here - epoxyfacts.com

Buy these products online (Low V and Wet Dry 700)

or call 603 435 7199:

(find and buy everything we sell here)

|

Best way to make on-line Purchases PAYPAL (tm) keeps your credit card info off internet web sites visit the PAYPAL site to sign up now |

(only primary products and no products that are high solvent and /or cannot be shipped all over the lower 48 state). This usually means Not For Sale in California.

|

Best way to make on-line Purchases PAYPAL (tm) keeps your credit card info off internet web sites visit the PAYPAL site to sign up now |

Customer feedback:

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

Dec 2008 from Doug: "The following is my opinion of a good company. My

affiliation is as a DIY end user. No recompense, no funny business: I've been

refurbishing our 1973 ketch and have done some epoxy work in that process. I've

never worked with epoxy before this. I talked to several local glass workers and

researched on line to learn a bit about epoxy. I searched for different vendors

and their prices. I settled on a place in New Hampshire called Progressive Epoxy

Polymers. (http://www.epoxyproducts.com)

My first thought was, what a mess of a website. I found it very confusing. Since I first came upon it, there have

been improvements made to make it more "user friendly". Aside from that, the site is most informative

to this beginning DIY's. I was won over by the explanations, descriptions of chemistries, MSDS's , suggested usages,

and personal responsiveness of the owner and his wife. I did a calculation of prices per ounce, approximating the

match of the different brand's products. I realize that there is no way I can say I'm comparing the same chemistry

of different brands. Nevertheless, Progressive Epoxy prices remain the best I have found.

I've used the Premium No Blush (~15 gallons), Low-V (~2 gal), a putty with kevlar, and some elastomeric stuff.

In addition I've used the fumed silica, micro balloons, ezy-thick, chopped glass & milled glass.

Progressive Epoxy Polymers is my epoxy source, I recommend them."

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

| "Hi there! This e-mail has no question but I was just looking through your site and I wanted to say that it's great! I was just looking around the internet to read about the subject of epoxy and no other site I visited was as helpful as yours. You are very knowledgeable in that subject and I admire that. Great work and I wish you the best! " - Gabriella 10/15 |

|

You don't find endorsements like this on other sites! |

Marine Related Links:

|

COPPER-AND-EPOXY (low v epoxy) BOTTOM COATING SYSTEM --- CUSTOMER VIDEO

Can actually apply underwater in small touch up spots |

|

The Marine Epoxy Everything Guide Everything from user reviews, repair examples, pricing issues and vendor evaluation tips

=====Basic No Blush Marine Epoxy Product Page =====Marine Epoxy Catalog page (multiple epoxies) =====Basic No Blush Marine Epoxy User Reviews / Feedback =====How To Evaluating Marine Epoxy brands and Vendors =====Marine Epoxy prices - what it really costs! =====Marine Epoxy amine blush - what is epoxy Blush? =====Boat repair examples using Marine Epoxy =====Dinghy Marine Epoxy boat repair case study =====Progressive Epoxy Polymer's marine web site =====Buy two part Marine Epoxy now =====Massive site of Internet boat links

|

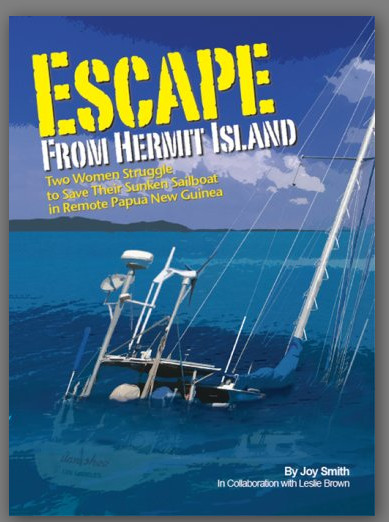

EMERGENCY YACHT UNDERWATER REPAIRA Case Study Using Progressive Epoxy Polymer's Underwater Epoxy - WET DRY 700 Underwater Epoxy and Corro Coat FC2100A (BUY NOW) read how our epoxies and customer service saved the day over a decade ago (2003). Read more (click here). Those products and service still available to you - call 603 435 7199 anytime and ask for Paul Oman. Underwater epoxy for Emergency hull repair - sinking yacht Case Study - now in book form at Amazon |

Available at Barnes and Noble and Amazon

|

|

BOAT BUILDING SUPPLIES AND INFO |

|

Non Blushing Marine Epoxy |

Marine Epoxies (find in

catalog) |

|

Epoxy Fillers / Thickeners |

Fiberglass Cloth |

|

"Stitch

and Glue" building |

Underwater Epoxy Repairs |

|

Varnish Info |

Varnish (find in catalog) |

|

Dinghy Repair |

Massive Boat Links Site |

| Email Us |

Call 603-435-7199 help/orders |

another similar (more

simple) blister repair site -

everything-epoxy.info/a-blisterrepair.html

|

Basic No Blush marine epoxy has a long list of private and professional boat builders. Most recently (2016 -2017) The Drummond Island Tall Ship Company built the 72 foot schooner Huron Jewel using Basic No Blush epoxy. (CLICK HERE) Over 160 gallons of epoxy were used - switching from the standard curing agent to the winter and summer curing agents as the seasons changed. Other professional builders include a Drift Boat company, a boat building school, and it was used to construct one of the boats in a 'row across the Atlantic' competition several years ago. Read about the professional restoration of a Thistle Class sailboat with our epoxies. Some of our other epoxies can be applied underwater have been used to rebuild a 100 year old wooden marine railway in 12 feet of water and repair and raise a sunken yacht at a Pacific Island Atoll. Read all about it in the book "Escape From Hermit Island" available at Amazon.com. From Stitch and Glue kayaks to 72 ft schooners to emergency underwater repairs - you can trust the epoxies from Progressive Epoxy Polymers, Inc. - a Better Business Bureau supporter/member. - Company VIDEO - 603-435-7199 |

"

|

WE'RE THE BEST SOURCE FOR ALL BOATING RELATED EPOXIES AND COATING! HERE'S WHY: No matter if your boat repair/building project is sitting in a 39 degree barn or sunk in 10 feet of water in the local harbor, our epoxies can save your day. We have Kevlar (tm) reinforced epoxies, marine non-blushing epoxies with bubble breaker additives (no one else has that!), two part polys in white or clear, and old fashion spar varnish. The clear has massive amounts of UV blockers. Need an epoxy barrier coat or an epoxy sealer/primer for that old weathered fiberglass hull? Does you hull have blisters? Need a thickened epoxy or DIY epoxy thickeners? Does the pontoon boat leak? Need to repair a spongy, rotting deck core? We can do all of that and also save your sinking or sunk boat AND help you build that stitch and glue kayak or 72 foot schooner (they used 200 gallons of our epoxy!). PROGRESSIVE EPOXY POLYMERS INC. (marine catalog) or just call us 603 - 435 -7199 - available nights and weekends. Email anytime. - TOP FAVORITE EPOXIES --- WEB BOAT REPAIR LINKS --- BOAT EYE CANDY! |

|

Buy With Confidence |

|

|

BBB Certified Approved vendor

|

Always find/confirm Better Bus. Bureau accreditation when buying online. If they have it, they would show it! |

|

member (Paul Oman MS MBA) |

NACE (Nat Assoc Corrosion Engineers) |

|

member (Paul Oman MS MBA) |

SSPC (Soc of Protective Coatings) |

|

Like Us On |

|

|

Like Us On |

|

|

Don't be fooled by slick and flashy websites designed by marketing firms and web designers |

|

|

QUESTIONS? READY TO ORDER? |

EMAIL OR CALL 603 435 7199 - ORDER ONLINE |

|

13 different marine epoxy -polyurethane coatings (www.epoxyproducts.com/ |

|

PROGRESSIVE EPOXY POLYMERS, INC also visit |

Inside Our Marine Catalog:

Section One TWO PART MARINE EPOXIES- CLEAR EPOXIES

basic no blush epoxy, premium no blush epoxy, esp 155 epoxy, low v epoxy

Section Two FILLERS THICKENERS ADDITIVES

fumed silica; microsphere/balloons; poly fibers; graphite, wood flour; EZ thick; rock flour

Section Three THICKENED EPOXIES - EPOXY PUTTIES, ETC.

wet/dry 700; splash zone; epoxy cream; splash zone a-788

Section Four TWO PART EPOXY PAINTS (barrier coats)

corro coat FC 2100; water gard 300; CM 15; liqua tile 11 72 potable water; rough coat; water prime

Section Five URETHANES AND NON-EPOXY COATINGS Aluthane (aluminum coating); LPU Marine; india spar varnish; acrylic poly uv plus, polyester poly

Section Six NON-SKID DECK COATINGS

walnut shell,; s15

Section Seven MARINE REPAIR PRODUCTS

pipe wrap; fiberglass tape (cloth); Capt. Tolley's Creeping Crack Cure

Section Eight MISC. MARINE PRODUCTS

short nap rollers; TA 661 (solvent free epoxy clean-up); 1 inch foam brushes; 2 inch bristle brushes; tongue depressors

Questions? / Phone order? / EMAIL / CALL 603-435-7199 EST / BUY ONLINE

GOOGLE SITE SEARCH - Click here Epoxy specific site search

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

Click here - Dozens of boat repair info links across the internet. - (everything is here!)

THREE MUST READ WEB PAGES

MPRICES - 2 part marine epoxy pricing issues - CLICK HERE -

MEPOXIES - comparing 2 part clear marine epoxies - CLICK HERE - (you are here already!)

EVAL4U - how to evaluate your marine/non marine epoxy vendor - CLICK HERE -

|

Marine Photo Gallery |

|

Search the EPOXY-ONLY World Wide Web search engine

for your Epoxy Related Search term

CLICK HERE FOR EPOXY RELATED SEARCHES

(QUESTIONS, ORDERS, ETC. WE CHECK EMAILS MULTIPLE TIMES EACH DAY AND ON WEEKENDS/HOLIDAYS)

Need More?

Ask the EPOXY GURU

Ask Professor E.Poxy

Click here - Company YouTube video (who we are!).

| "Hi there! This e-mail has no question but I was just looking through your site and I wanted to say that it's great! I was just looking around the internet to read about the subject of epoxy and no other site I visited was as helpful as yours. You are very knowledgeable in that subject and I admire that. Great work and I wish you the best! " - Gabriella 10/15 |

|

You don't find endorsements like this on other sites! |

|

"Hi Paul, ---Thank you so much for all the info. Each time I spoke with you, I found you to be a very helpful, personable individual. You seemed genuinely interested in helping me get the right products and making sure that I know exactly the best way to apply it for optimum results. Sadly, in today’s business world, those are not common traits. It definitely was a pleasure to do business with you ( as cliche as that saying is.) I definitely will recommend to anyone who needs your products. Best wishes for continued success. Sincerely, Julie" (6/2019) |

|

Let's stay connected. It's a win-win situation. Receive our online NEWSLETTER by emailing us your name and email address. |

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms. CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option.

RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Progressive Epoxy Polymers, Inc.

603.435.719

Pittsfield, NH 03263

Navigation Bar frame replacement CLICK HERE mobile friendly key site links