PROGRESSIVE

EPOXY POLYMERS, INC.

epoxyproducts.com

No Sales Tax applied. Save Money, you're shopping in Tax Free New Hampshire

Click here - YouTube video. Learn about Progressive Epoxy Polymers Inc.

MPRICES - 2 part marine epoxy pricing issues - CLICK HERE -

MEPOXIES - comparing 2 part clear marine epoxies - CLICK HERE -

EVAL4U - how to evaluate your marine/non marine epoxy vendor - CLICK HERE -

Boat links - dozens of links to boat building

repair sites (click here)

PRODUCTS COVERED IN THIS

MARINE CATALOG SECTION

1) CORRO COAT FC2100A -- FC2100F

2) WATER GARD 300

3) CM 15

4) LIQUA TILE 1172 (POTABLE WATER EPOXY)

5) ROUGH COAT

BELOW ARE BRIEF "CATALOG LISTINGS" FOR THESE PRODUCTS

INCLUDING SOME GENERIC INFORMATION ON THE PRODUCT.

1) CORRO COAT FC2100A and/or FC2100F epoxy paint

**

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE (two different online stores) /// RETURN TO MARINE CATALOG HOMEPAGE **0% VOC --- Shipped UPS ground only.

The only Epoxy Paint reinforced with Kevlar (tm) microfibers and feldspar ceramic for an incredible hard and tough product plus enhanced abrasion resistance.. Can be applied Underwater too! Nothing else like it in the market.

Extreme high epoxy performance at an affordable price. A non-hazmat, 100% solids epoxy. Kevlar (tm) micro fiber reinforced for chip resistance, loaded with feldspar/ceramic for extreme toughness and mechanical properties. This water tolerant epoxy will bond to wet or damp surfaces and can even be applied underwater. Odorless, so ideal for application in confined spaces. Paint pad or brush on at 15 mils without sagging (thinner if roller applied).

Ideal for barrier coats. Coverage about 125 square feet per 1.5 gallon kit.This epoxy has the thickness and texture of gray applesauce.

Advantages: abrasion resistance, cycloaliphatic curing system, cold weather version available (i.e. the FAST version) for use when temperatures are under 50 degrees; 1.5 gallon packaging

This product comes in several 'flavors:

FC 2100 A - the original version (formerly FC 2100 epoxy) - 2:1 mix ratio, NON HAZMAT to ship - can be shipped by air.

FC 2100 FAST - a fast version (actually used for application cold temperatures - say 40 - 55 F)

This FAST version (like the high temp version) requires hazmat or ORM-D shipping (must be shipped via ground only lower 48 states - no extra shipping charges).

This product has its own web page - CLICK HERE

More on Kevlar (tm) reinforced epoxies like this one CLICK HERE .

Texas Coast - Morgan 41 - about 1980

Common applications: sheet pilings, tanks - pits - sumps - basement leak repair, marine barrier coat, marine pilings

PRICING

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE

FC 2100 A - 1.5 gallon kit - $240 color: light gray

FC 2100 A - 48 oz. kit ( 0.375 gal) - $95 light gray

FC 2100 FAST - 1.5 gallon kit - $255

FC 2100 FAST - 48 oz low temp (FAST) version - $107

LINK TO A SOMETIMES MASSIVE SITE SUB-PAGE INCLUDE KEY LINKS, CUSTOMER COMMENTS, TABLES PICTURES, ETC. FOR THIS PRODUCT. CLICK HERE. PLENTY TO READ AND STUDY! DATA AND MSDS SHEETS CLICK HERE

2

) WATER GARD 300 epoxy paint**

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE (two different online stores) /// RETURN TO MARINE CATALOG HOMEPAGE **0% VOC --- Shipped UPS ground only. Only shipped within the lower 48 states

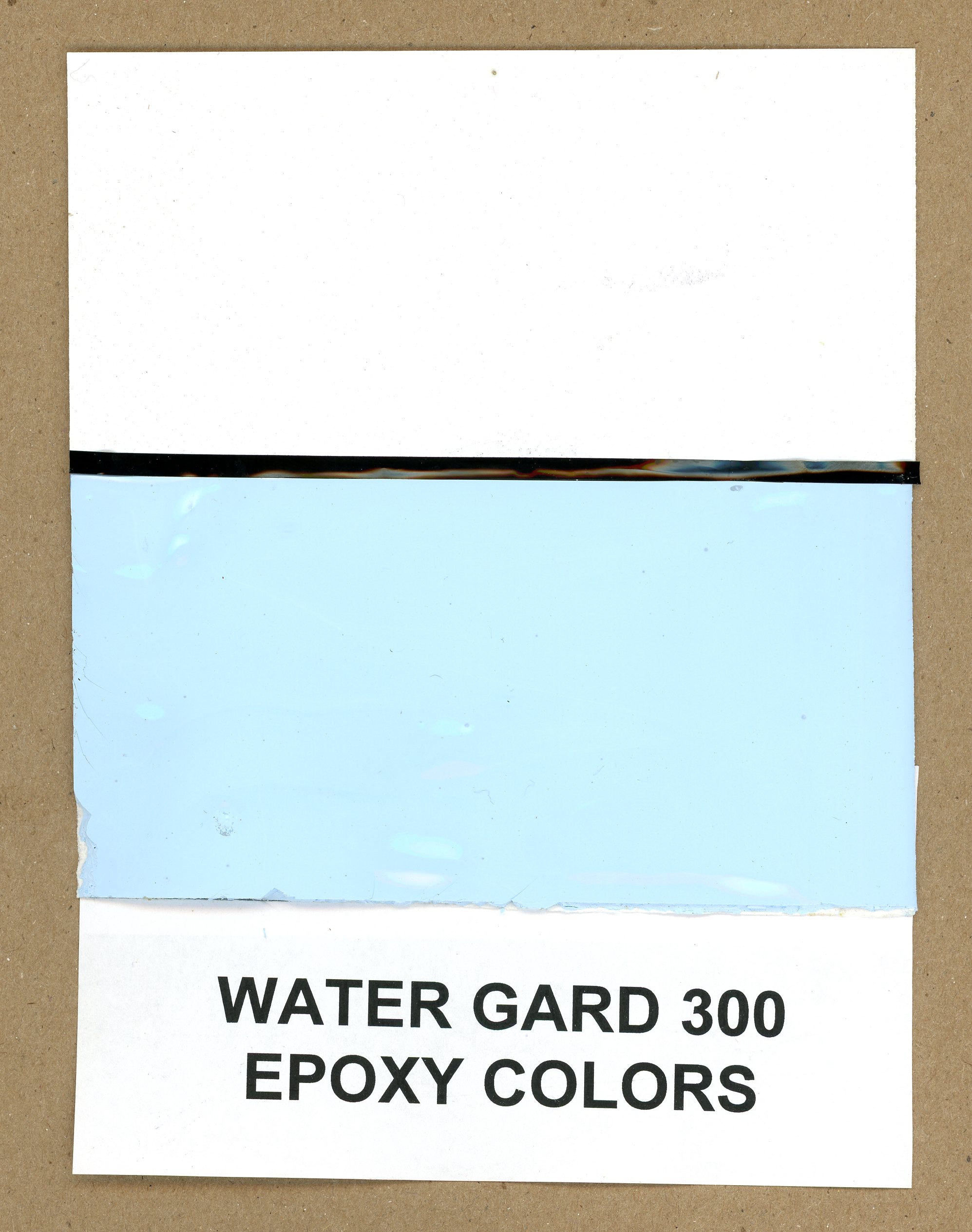

An all-surface, white, light blue, epoxy that goes on at about 12 mils (with a brush or paint pad, thinner if applied by roller). Suitable as a BILGE COATING OR (MORE COMMONLY) A HULL BARRIER COAT EPOXY (a 3 gallon kit will cover 400 square feet).

Mix 2:1 by volume.

Colors: slow yellowing white, light blue. We were impressed with the lack of rapid yellowing of the white color

Advantages: longish pot life, selection of colors, cycloaliphatic curing agent, non hazmat to ship so can ship overnight; uses a cycloaliphatic curing agent. This is a hard, rigid coating - very tough but if you think you need some 'flex' see our CM 15 listed on this page.

If you do decide to go with two coats (common if the entire gel coat has been removed) using a different color

for each coat allows you to estimate how deep any future chips into the hull are (i.e. color coded layers!), as

well as spotting thick and thin spots in the second coat.

Thistle sailing - Long Island Sound - Milford, CT 1973

Common applications: bilge coating, marine barrier coating, apply underwater swimming pool touch up paint

PRICING

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE

3 gallon kit - $499 (colors light blue or white)

3 quart kit - $270 (light blue, white)

1.5 quart kit (0.375 gal) - $195 includes 2 stab brushes and 2 sets of latex gloves - FREE SHIPPING LOWER 48 STATES.

(Special Notes): none

Hi Paul,

I think we have some converts.. We barrier coated the bottom of my boat

and the guys loved your epoxy.. They could not believe how easy it went

on and how fast it built up.. they also mentioned they liked the colors

blue and white. They commented on how nice it was to have

contrasting colors to see where they left off from coat to coat... I think you will

start getting orders out of Daytona Beach very soon... I have been

using your epoxy myself and find it is very easy to work with... I'm

glad I took the chance on you. Your epoxy does everything you said it

would.. Thanks Mike D.

LINK TO A SOMETIMES MASSIVE SITE SUB-PAGE INCLUDE KEY LINKS, CUSTOMER COMMENTS, TABLES, PICTURES, ETC. FOR THIS PRODUCT. CLICK HERE. PLENTY TO READ AND STUDY! DATA AND MSDS SHEETS CLICK HERE

3

) CM 15 epoxy paint**

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE (two different online stores) /// RETURN TO MARINE CATALOG HOMEPAGE **VOC 181 g/l --- Shipped UPS ground only. Only shipped within the lower 47 states (not for sale in California)

EXCELLENT WARM WEATHER EPOXY - (long pot life - warm weather ) QUALITY

EPOXY MASTIC PAINT - with lots of extra flex - compared to the more brittle, traditional epoxy paints.

CM 15 is a high solids (82%), two-part epoxy designed with a long pot life, slow cure, and outstanding flex. It

contains proprietary resins, wetting agents and penetrants for superior bonding.

It's long pot life, and low/medium viscosity make it suitable for application in

the hottest of climates. Designed with a lot of internal flex, CM 15 can handle

thermal expansion and contraction of large surfaces without failing. With a

coverage rate of between about 150 square feet per gallon, this is an affordable epoxy coating. Colors:

ivory, black

Because if its long pot life and solvents, this epoxy applies more like "regular" paint than do the other epoxies. Note that at 60 degrees temp, painted surfaces are still tacky after 20-24 hours, so recommend for use above 70 degrees (or in hot weather when other epoxy paints will 'set up' too fast).

Two coats of this more flexible epoxy will make a suitable marine barrier coat (it is thinner than the Water Gard 300 barrier coat epoxy). Two coats of contrasting colors is a nice way to monitor coating thickness/ application quality control, etc.

Additional product information/mentions about CM 15 can also be found at the following site(s) - https://www.paints-coatings-epoxies.com/a_cm15_epoxy_paint.html

| CM 15™ EPOXY PAINT |

PRODUCT PRO AND CON REVIEW |

| PRO | Lots of flex (for surfaces that expand/contract, flex or move), long pot life |

| CON | Best if applied in temps over 75 degrees Not for sale in S Calif |

Common applications: hot weather (summer) epoxy paint, barrier coat for flexible hulls, common epoxy paint for pontoon boats

PRICING

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE

1 gallon kit - $120

Paul (4/2014):

Over the course of the last three days, I applied the black and then the ivory CM-15 epoxy paint to my fiberglass sailboat. It applied beautifully. The temperature ranged from 70 - 75 degrees and the humidity was in the 40-50% range most of the time. The last coat went on last evening about 6:30 pm with humidity creeping up a bit, due to an impending rain storm. Sanding at 24 hours was almost o.k.....not very much clogging, but some. I waited until 36 hours and it sands without any clogging.

DETAILS: 23' Sonar sailboat; best I could measure, about 140 sf to paint.

Mixed 1/2 of each gallon kit plus some solvent (2 oz) for each coat. Two coats of black, followed by two coats of ivory...all coats applied within 8-12 hours of each other.

Applied using your 9" close nap roller covers. Each coat took about 45 minutes to apply. Mixed......applied paint. No pot life issues and each half batch covered well with about 1/2 cup remaining after coverage. The last coat of ivory, I tried to apply more heavily and used all the paint, just as I finished.

The surface is why I would call a mild orange peel texture...not glass smooth. As soon as I can sand, I intend to use a longboard with 120 grit to knock the high points down.

Thanks for a great product. Mark -from MO

DATA AND MSDS SHEETS CLICK HERE

4

) LIQUA TILE 1172 potable water epoxy paint**

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE (two different online stores) /// RETURN TO MARINE CATALOG HOMEPAGE **0% VOC --- Shipped UPS ground only. Only shipped within the lower 48 states

| LiquaTile 1172™ EPOXY PAINT |

PRODUCT PRO AND CON REVIEW |

| PRO | APPROVED STANDARD 61 POTABLE WATER EPOXY PAINT - APPROVED FOR TANKS AS SMALL AS 50 GALLONS. THICK/SOLVENT FREE COATING. |

| CON | 5 DAY CURE BEFORE PUTTING INTO POTABLE WATER SERVICE - ONLY 48 STATES ONLY - NO AIR SHIPPING |

At long last, an new generation of potable water

epoxy. A potable water approved epoxy paint for tanks as small as 50

gallons. 99% of all potable water epoxies require tanks of 1000 gallons (or even

5000 gallons). This is a new generation of potable water epoxy chemically

re-formulated for much smaller tanks. Also has certified approvals for lead

content (not commonly included with potable water epoxies.

Mix ratio is 2:1 by volume. Color - white. A 3 quart kit will cover about 50 - 75 sq (about a 100 gal tank) by short nap roller. In hard to reach area, folks will use compressed air from an air compressor to blow the epoxy into hard to reach corners.

See product specs and details on this water potable water, next generation epoxy paint. Specs click here

This product has its own POTABLE WATER web page

|

|

|

|

certifications also available for printing etc. CLICK HERE

Common applications: potable water epoxy approved for tanks over 50 gallons

PRICING

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE

3 quart kit - $278

"Hello Paul - I just wanted to say thank you for your help and knowledge. I am very grateful. I finished painting my water tanks (liqua tile 1172 epoxy)and after 5 days of curing, I filled them and closed them up yesterday. My only regret is that all this wonderful work I’ve done is now closed up and buried. You provide a great service and I just wanted to say that it is appreciated. All the best." - Bryan

AND MSDS SHEETS CLICK HERE

5) ROUGH COAT epoxy paint

**

EMAIL //// ph 603.435.7199 EST //// BUY ONLINE (two different online stores) /// RETURN TO MARINE CATALOG HOMEPAGE **VOC 249 g/l --- Shipped UPS ground only. Only shipped within the lower 47 states (Not for sale in California)

ROUGH COAT™ EPOXY PAINT |

PRODUCT PRO AND CON REVIEW |

| PRO | Epoxy floor coating with fine non-slip grit already in it. Solvent based so pot life measured in hours. |

| CON | Thin coating, only available in 1 color - tan -(can be painted over) - subject to blush - apply indoors if possible |

This is our special floor epoxy with grit already mixed-in for non slip. It is solvent based, flexible, and rolls on at about 160 - 180 square feet per gallon kit. The solvents are necessary as they allow the grit thickened epoxy to roll our nicely and then 'shrink' down as the solvents evaporate away, allowing the grit to become fully exposed. We just couldn't achieve this nice distribution without the solvents. The end result is a floor with a grit surface. Texture is rougher than you would see in a shower, but still not 'industrial rough' - similar to what I have seen on custom wooden boats decks. One coat is fine, but two coats really masks the 'roller direction pattern' of the grit sometimes seen with only one coat, giving a slightly more textured surface with a more random pattern. It can be brushed on too, but the brush marks are very obvious. Unlike the Industrial Floor epoxy, but like the Water Bond epoxy, Rough Coat will not hide cracks and flaws on the surface. If you need to 'hide' cracks etc., use a base coat of the Industrial Floor Epoxy or our clear watery Low V epoxy under the Rough Coat. Being solvent based, pot life is measured in hours, not minutes.

A white film can sometimes form on the surface within the first 1 - 3 days if temps. are cool and dew/condensation form. Best applied indoors or in warm summer weather. This is amine blush.

The color is a light tan or khaki. We selected this color because it has enough yellow it shouldn't show UV yellowing but it is light enough in color that you can topcoat it with a layer of latex or enamel in whatever color you want (and still have a non-skid texture). We have seen boat decks and patio decks etc. in this light tan woody color, and it is a color we don't have any other epoxy in, so it seemed like a good color to stock.

In terms of color and texture it seems to match the appearance of 'fine sharp sand in flat enamel' on small custom made wooden boats I've seen at the WoodenBoat show in Maine. The part A looks like whipped cream in the can but when mixed with the liquid part B it forms a nice coating.

Texture is suitable for bare feet.

CANNOT BE SOLD IN SOUTHERN CALIFORNIA

color matches (tan):

we tried to sort of match Benjamin Moore Classic Collection Cafe Royal 2B - 1130

Common applications: boat decks, home patio or walkways

PRICING

//// ph 603.435.7199 EST //// BUY ONLINE1 gal unit - $101

8 oz unit is $23.50 but needs to be included with additional epoxy order (too expensive to ship alone - shipping could easily be over the cost of the product

DATA AND MSDS SHEETS CLICK HERE

MARINE CATALOG

SECTION LINKS

Your are currently in Section 4

***********

Section One MARINE - CLEAR EPOXIES sometimes called 'goo' ***********

Section Two FILLERS THICKENERS ADDITIVES ***********

Section Three THICKENED EPOXIES - EPOXY PUTTIES - sometimes called 'goo', ETC. ***********

Section Four EPOXY PAINTS (barrier coats) ***********

Section Five URETHANES AND NON-EPOXY COATINGS

Section Six NON-SKID DECK COATINGS ***********

Section Seven MARINE REPAIR (fiberglass cloth etc) PRODUCTS ***********

Section Eight MISC. MARINE PRODUCTS ***********

Legal Stuff / Returns

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option.RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Navigation Bar frame replacement CLICK HERE mobile friendly key site links