epoxyproducts.com

SECTION D - CLEAR COATINGS AND EPOXIES

sub-page for BASIC NO BLUSH epoxy

Includes key links, customer comments, tables,

pictures, etc for this product

RETURN TO SECTION D OF ON-LINE CATALOG

Often also used to reseal epoxy/pebble stone decks (coverage 200-250 square feet per 1.5 gal kit. Also see our special thick roller for this application - Section i Industrial catalog misc. section)

More customer feedback and comments on Basic No Blush resin- CLICK HERE.

This product has its own web page - CLICK HERE

MISC. INFO

|

Why Basic No Blush (tm) epoxy is the BEST in its class: 1. A formulated blended resin system (not repackaged raw chemicals) 2) Uses NON BLUSHING curing agent for blush free results 3) not too thick, not too thin, not too brittle - ever see an epoxy surface with millions of tiny cracks? It is brittle, repackaged (see #1) not formulated epoxy 4) the only marine type epoxy with bubble breakers for superior flaw free finishes and uniform properties and appearance and allows for thicker, multiple layers with better clarity 5) the only epoxy adduct marine type epoxy for superior enhanced properties (standard cure only) 6) strong user support / feedback 7) 24/7 support email marineepoxy@gmail.com 8) less expensive than the other formulated epoxies which still don't have many of the advantages listed here |

|

Epoxy Crazing Notice/Warning |

|

There are two types of Marine Epoxy Vendors: 1) discount, bulk, REPACKAGERS who simple buy drums of raw resin and raw curing agent(s) from the big chemical companies and fill plastic jugs for resale; 2) FORMULATORS take the raw epoxy chemicals add to them to enhance and improve the raw "moonshine" into a "fine whiskey". Learn more repackagers/formulators. Our Basic No Blush (tm) is a formulated non blushing epoxy by Progressive Epoxy Polymers, Inc. (homepage). that includes additions for reduced brittleness and exclusive (only we have it) bubble breakers for a more perfect looking finish. Basic No Blush is the least expensive of the formulated epoxies and considered the best marine epoxy by many ex-users of the other formulated epoxies. REPACKAGED EPOXY WARNING: Over the years I have seen and had reports of non-formulated, raw resin/cure epoxies (which are extremely hard and brittle) becoming crazed with millions of cracks (like shattered safety glass) in outdoor settings that experience big changes in temperature. Formulated epoxies all seem to be 'fixed' to allow for this expansion and contraction without cracking by making them less brittle and better able to handle internal stresses. |

|

Marine Catalog ///// Stitch n Glue ///// Epoxy Only Google Search ///// Epoxy Guru Help Site ///// Marine Boat Epoxy Etc. Links |

| "I've been using the Basic No Blush epoxy on all my own stuff, and using up all the West epoxy on most customers boats. When the West is finally gone I'll only be using your epoxies. Good stuff. I'm rebuilding an old Rybovich so a big order in the future..." Patrick (comment with on-line order 9/4/07) ---- Order No Blush online |

| THIS PRODUCT | xx | EMAIL US | xx | |

| air shippable | cycloaliphatic system | |||

| no nonyl phenol | epoxy adduct system | xx | ||

| multi curing agents | xx | bulk pricing | xx | |

| solvent free | xx | no Calif. sales | ||

| 2 part epoxy | xx | 2 part poly | ||

| apply underwater | bubble breakers | xx | ||

| favorite(s) product list | xx | data sheets | xx | |

| PACKING - jugs/bottles | xx | PACKING - cans | xx | |

| find in non marine cat | xx | find in marine catalog | xx | |

| PRICES/ind/commercial | xx | PRICES/marine section | xx | |

| BUY online | BUY online | xx | ||

| home page | xx | contact page | xx |

|

ITEMS OFTEN PURCHASED WITH THIS PRODUCT: Basic No Blush |

|

* India Spar Varnish

(in non epoxy section) *Fiberglass cloth/tape * Epoxy rollers (2 kinds - thin for marine and thick for stones) * 2 part clear poly with UV blockers (no Calif sales) * Marine Spar Varnish top coat * Fillers and thickeners * Pumps for 1.5 gal units * Film thickness gauge * Fast or slow curing agent options * TA 155 (trowel aid) for creating pebble decks |

| Find in 1-page summary site (marine) with links and prices |

| Find in 1-page summary site (non-marine) with links and prices |

APPLICATION EXAMPLES

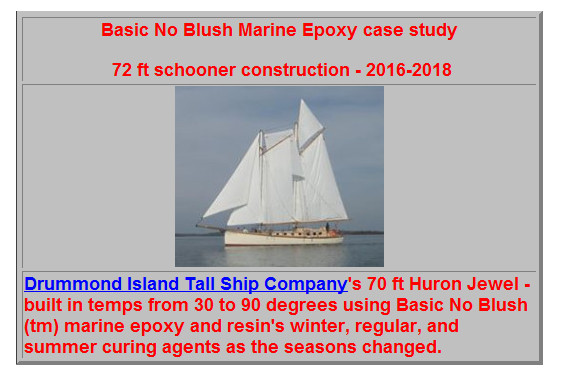

Our Winter Curing Agent - means 'New England'

winter temps (30's and 40's). If your winter temps

in the 50s generally, order the regular curing agent.

|

Basic No Blush™ marine epoxy resin -in space!It is not just about boats or pebble decks - Basic No Blush epoxy is being used by amateur rocket builder Dr. Dennis McClain-Furmanski PhD LINKS: Light

weight replacement airframe -

http://www.rocketreviews.com/reviews/all/mod_aero_black_diamond.shtml |

stone walkway resealed

with Basic No Blush epoxy

|

.

What is a Puddle Duck Racer? (

visit their web site - PDRacer.com) Our BASIC NO BLUSH ™ marine epoxy is the endorsed epoxy within the Puddle Duck community. |

|

Hello Paul -- Sending photos of the shower my wife Regina and I designed. We wanted the shower floor to convey a beach feeling. To achieve the effect, white cement was used and tiny sea shells were pressed into the surface. After the concrete cured I took your advice on which epoxy to use to encapsulate the sea shells ( Basic No Blush).It was a bit tricky to keep the epoxy from all flowing into the drain. :-) After brushing on three coats I used a hole saw to cut thru the Basic No Blush epoxy that had collected over painters tape covering the drain. Heeding your warning that wet epoxy is dangerously slick, I finished the job with a top coat of acrylic sealer with a glass dust nonslip additive. The results are beautiful and safe.Thanks for the advise and great epoxy product. -- Best Regards -- Mike |

|

USER COMMENTS

|

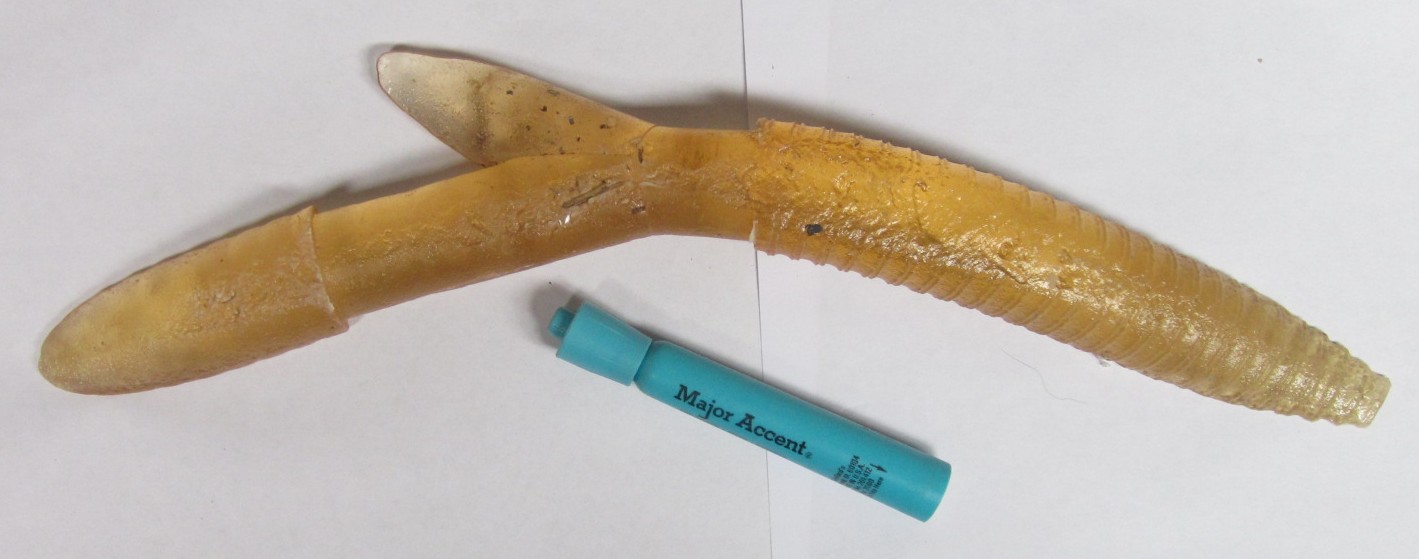

Paul,

Just thought you might get a chuckle out of this mistake of mine. I was filing up a rotten bulkhead with epoxy and it leaked out, ran down the shower wall and down then shower drain. This is the result of the epoxy setting up in the drain pipe. Doug |

Austin xxxxx @ alum.mit.edu = (5/2013) "Great Product. Have used it many times and recommend it to others often."

To: <pauloman555@yahoo.com

"Excellent web site!!! I have started testing your "Basic No Blush Epoxy". Wow! Good stuff and affordable

too. I intentionally incorrectly mixed your product to test its sensitivity to mix ratio variations. Very, very

forgiving. The pot life is very consistent even with some variation in ratio and set up is consistent as well.

It also does not seem to flash as easily as other epoxies I have worked with. I got by working in the 16 oz. mixing

cups without having to pour to a wider flat bottomed container. I usually wait till an epoxy starts to flash or

just slightly heats up in the cup before I pour it into an ice cream bucket. That is of course not a summer time

practice but my shop can get down to 60 F. in the winter. But your product did not seem to heat a lot. I was even

a little nervous about it setting up but it cured like a champ! I am very happy with your Basic No Blush and I'll

be back for more." Sincerely yours -- J.A.

Joe wrote: "FYI..... I have used your epoxy on a lot of various applications, from thinning it for deeper penetration/sealing, to thickening for bonding multiple wood components and the stuff is great. All exterior wood gets one coat of thinned epoxy, then 2 coats full strength. then i have applied spar varnish. I have had a piece of hon. mahogany in a bucket of water for 3 months and the finish is still perfect and completely sealed. You guys are helping me restore a 35 yr. old wooden cutter, Thanks again." Joe

I purchased a basic no blush sampler back in March to try and make some aquarium decorations.

I used PVC pipe, epoxy coated aquarium rocks and your epoxy with a fair amount of thickener. I used your advice

and waited a week before using to let the epoxy cure completely and put it in the aquarium. The pictures show the

results. The blue one has been in the aquarium since the middle of May (the picture is from a week ago) and the

pink one is for my daughter.

RETURN TO

SECTION D OF

ONLINE CATALOG

Legal Stuff

/ Returns

NOTICE:

Legal notices, Terms of Service, warranty information, disclaimers, health

warnings, etc. are required reading before using web site, ordering and/or

using Products. Any such use and/or ordering, online or by telephone, shall

constitute acceptance and knowledge of all such terms.

I take good care of my tanks, testing and maintaining the water quality and, making sure the fish are healthy.

The blue one is in a 90 gallon with almost 30 fish and 2 frogs and I haven't experienced a single problem.

I could probably use any epoxy but your customer service was exceptional. Understanding that epoxy is non toxic

after it completely cures and to watch for any additives that may be toxic were key to a successful experiment.

Thank you, Tim 10/09

RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Navigation Bar frame replacement CLICK HERE mobile friendly key site links