PROGRESSIVE EPOXY POLYMERS, INC.

Pittsfield NH 03263

Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Web Product CATALOGS

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

We are the only technology based coating/epoxy/resin company that actively encourages your phone calls, not just during our East Coast work hours but also after/before hours, evening, weekends and even holidays. We're available when you are. We form a personal relationship with our customers and freely share technical information, how to-advice, product information and tips-and-tricks. Speak with a non-salesman technical professional with over 25 years of experience in the resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors, tables, boats, leaks, rot repair. We handle it all! We are an 'always available,' one-on-one, technical/scientific, coating company (watch our video). We are NOT one of those fluffy/slick mass sales firms the dominate the internet selling cheap third party (made in China???), low end epoxies and coatings with no real knowledge of what they are selling and quotas to sell to as many people as possible. 603-435-7199 (east coast time).

ABSOLUTE BEST SOURCE for epoxy information, options, USA made products, 24/7/365 help, and support

Buy your resins/chemicals from a coatings company, not a marketing firm

Multiple epoxy options - No one single product for everything!NO SALES TAX - You are shopping in TAX FREE New Hampshire

Doing a Epoxy Penny Floor? It is similar in some ways. Visit our Penny Floor page instead of this web site

Your Host and Tour Guide:

Paul Oman, MS, MBA - Progressive Epoxy Polymers, Inc. (floor epoxies, marine epoxies, underwater epoxies, repair epoxies)

Member: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings)

Board member: Friends of the Suncook River - 501(c)(3) non profit ----- Founder: Friday Night Paddlers .

"Professionals helping Professionals"

(Our prices include all the email and 'returned phone call' support, handholding, help, advice you need or want. That's why our customers buy from us!)

|

Best advice from an Epoxy PRO on how to avoid a $$$ DIY epoxy floor disaster (you won't learn this on any other epoxy floor site) If any of the following apply or might apply to you: 1) no vapor barrier, or don't know if there is a vapor barrier under your slab; 2) suspect there might be moisture issues in/on the slab; 3) suspect the concrete was not 'vibrated down' and contains lots of air spaces (which can cause bubbles and blisters in the wet epoxy); 4) cannot professionally prep the floor (usually means a shot blast contractor); 5) any existing coating on the floor is peeling and lifting; 6) the concrete seems dusty, gritty, weak or crumbling; 7) you are worried about "hot tire pickup" lifting off your epoxy floor; 8) you have oil stains on the floor (especially OLD oil stains)....... If so, consider putting an inexpensive epoxy primer / sealer (such as ESP 155 - an Internet Favorite epoxy coating - not for sale in California) on the entire floor or over those potential trouble spots. Then wait a few weeks or months and see what happens. If everything looks great it is very likely that a 'fancy' epoxy top coat will be successful and probably issue free. You might even decide to just keep the sealed floor and skip the thicker mostly decorative (or at least thicker and pigmented) epoxy top coat (such as 0% VOC INDUSTRIAL FLOOR EPOXY). If problems developed with the thin, nearly clear ESP 155 epoxy sealer, it is not that big a deal. No worse than having some deck/porch enamel paint lift and peel. You won't trip over it, it is not so 'in your face', and you saved big $$$ that you would have spent on the epoxy, paint chip, top coat. Some existing concrete surfaces are just not good candidates for an epoxy coating. QUESTIONS? email OR call 603 435 7199. Floor Links Page. Learn all about epoxy floors. |

Epoxy garage coatings (EPOXY PAINT) are often used on floors because of their reputation for toughness

and durability from wear and chemicals. On the downside, epoxies tend to yellow and lose their gloss, or even chalk,

when exposed to sunlight.

Floor coatings seem to be an area where many epoxy manufacturers cut corners to lower price. These low cost ‘watered-down'

epoxies also have ‘watered-down' performance. As with most things, you get what you pay for. A call must be made

as to the quality of the epoxy needed for the job at hand.

It would seem that painting a floor should be a simple matter and one without much chance of failure. Unfortunately

painting concrete floors is not so fool proof. Many things can go wrong and given the cost of coating a large area,

and fixing things if something happens, the decision to coat a concrete floor should not be taken lightly.

Epoxy floor paints can fail/peel for lots of reasons including: a layer of dust/dirt on the surface, a weak surface

‘crust' common with brand new concrete, moisture in the concrete, migrating moisture or water vapor and osmotic

forces at play AFTER the coating is applied, greases and oils in or on the concrete some of which do not seem removable

with even the best degreasers. Kitchens (especially around deep fat fryers etc.) and food processing plants are

notorious for rejecting their coatings no matter what sort of preparation is attempted.

Existing garage coatings can sometimes, but not always, be top coated with the epoxy. This assumes that the old

coating is bonded well to the concrete, that the epoxy will not soften or alter that bond, and that the epoxy will

bond to that particular coating. Only an actual test will provide verification.

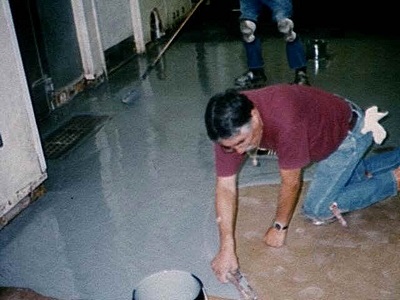

Often sections of the floor will also need to be patched, leveled, filled or repaired. The contractor has several

options here and a wide range of products to select from including epoxy mixed with sand to form a slurry patching

material.

Commercial epoxy garage floor applicators will generally prepare the floor using a shot blast machine that bombards the

concrete with tiny steel balls that remove surface coatings and open up the concrete to accept the epoxy. Home

owners can wash the concrete with a solution of 1/3 muriatic acid to ‘acid etch' the concrete. Flush with plenty

of high pressure water to remove all traces of the acid -- and keep your fingers crossed. There is no way to tell

if your acid treatment worked or not.

Some people think a thick epoxy garage floor is better but this is not often the case. If a gallon of epoxy will

coat 100 square feet, a cost per gallon of $100 is not out of line. Applied at a 1/4 inch and that same gallon

will cover less than 7 square feet – way too expensive at $100 per gallon. At 7 square feet per gallon, only the

cheapest, often inferior, epoxies make economic sense.

The best epoxy paint floors are actually quartz floors held in place with epoxy. In other words, a layer of epoxy saturated

to excess with sand or some sort of anti-skid abrasive (often attractive colored sands are used) and then a sealing

top coat of more epoxy. These epoxy-sand-epoxy sandwich floors are two coat systems. For less demanding applications,

single coat systems are an alternative. The epoxy can be applied without any abrasive in it for a smooth, slick,

and initially shiny floor. For slip protection either fine rubber pellets or fine grained sand can be lightly broadcast

into the wet epoxy and ‘back-rolled' to more evenly distribute the abrasive and to completely coat it with the

epoxy. With a one coat system the strength comes from the epoxy, with a two coat system is comes from the much

tougher quartz filler.

An attractive alternative offered by some epoxy floor firms (including us) is a colorful chip floor. These very

attractive epoxy floors utilize a coat of epoxy with half inch colored vinyl flakes sprinkled on top and nearly

covering all the epoxy. Bank-rolling locks them in place and a final clear, sealing epoxy topcoat completes the

job.

The keys steps of any epoxy floor are surface preparation, which is critical, and the application of a one or two

coat system. During that process there are important decisions to be made. Misjudgments can be costly so experience

and practice are attributes worth seeking out.

|

WATER BASED (WATERBORNE) EPOXY FLOOR PAINTS

|

SOLVENT FREE (or low solvent) EPOXY FLOOR PAINTS |

|

(comparison table) Water Bond Epoxy (tm) med. gray only |

(comparison table) Industrial Floor Epoxy (tm) light gray or beige only |

|

* actually contains voc solvents plus water (restricted in some locations) * slight odor * very long pot life * water clean-up * large coverage per gallon * good color stability * very thin coating - will not hide flaws (may highlight them) * somewhat breathable and some penetration into concrete (good adhesion) * generally less used than solvent free epoxy floor paints * can be primer /sealer under other epoxy (non epoxy) floor systems

|

* no solvents or

VOC issues (solvent free only) * generally odorless * wet thickness equals dry thickness (no shrinking) * thick coating hides flaws and imperfections * can trap air bubbles from expanding air in concrete * shows epoxy yellowing in UV * coverage about 150 sf per gallon * creates vapor seal (radon etc) * can have adhesion issues on damp moisture rich surfaces * tough and durable * standard commercial - professional floor solution * short pot life - working time * use with colored chips or colored sands * works with chips - sands - multi-coat systems |

|

FIND WATER BOND EPOXY IN CATALOG ASK PROFESSOR E . POXY (help link) PROGRESSIVE EPOXY POLYMERS, INC (SINCE 1992)

|

FIND INDUSTRIAL FLOOR EPOXY IN CATALOG ASK PROFESSOR E . POXY (help link) PROGRESSIVE EPOXY POLYMERS, INC (SINCE 1992)

|

1) materials for an epoxy floor will cost from $0.60 to about $4.00 per square foot

2) Using colored quartz sands or vinyl chips provided an attractive floor, in the $2.50-$3.50 price range per square foot. However, because of the cost and packaging of this sands or chips, it is not practical to consider this an option for any floor less than about 500 square feet.

3) Yes, you can do an epoxy floor yourself. It is best to have at least one helper when you actually do the work.

4) Surface preparation is the hardest and most critical step. It could make or break the job and the decision of how much surface preparation (and what kind) is strictly your own.

5) A good rule of thumb is to pour some water on the concrete. If it soaks in quickly and evenly, the floor is probably suitable and ready for epoxy coating.

6) Grease and oil stained areas are going to need REPEATED degreasing with HOT water and hopefully high pressure water. Use the water test in #5 to check how you are doing. Many contractors will 'seal' the degreased areas (see our surface preparation page - click here) to make sure deep down greases do not migrate back to the surface and cause problems. Smart contracts will often not accept jobs with potential grease or oil problems.

7) Check the concrete for active water migration that also could ruin or rule out an epoxy floor. If crystals keep forming on the concrete, your probably have a problem. Crystals or not, tape a sheet of plastic (tape all the way around) - about 3 ft by 3 ft - to the floor and leave it there for a few days. Remove the plastic. If the surface is full of water, you probably have a problem. Epoxy might not be for you.

8) Figure out how much you are willing to spend per square foot (and figure out how many square feet you have to cover).

9) Decide on a one coat system (with or without a bit of grit scattered in), or a two plus coat system which uses colored quartz sands, vinyl chips, or even plain sand. For serious commercial applications and max. anti-slip, for max. wear, and for best appearance, a two coat broadcast system is required. Consider a one coat system only for light use. One coat systems start at about $0.40 per square foot, a two coat system begins at about $1 per square foot. Consider a water-based epoxy system too! - click here.

10) All epoxies yellow and lose their shine quickly. White will turn yellow (we offer sort of a pre yellowed beige color), clear topcoats will turn yellow. Gray will become a greenish gray in sunlight. We do have a product that will absorb the UV and keep the epoxies from yellowing. It cost about $0.40 per square foot. The most 'color fast' approach is to use our brick (tile) red epoxy as the top surface coat in a one or two coat system (no clear coat, no colored chips or colored sands) because the red does not show yellowing. Another alternative is to use a 2-part polyurethane clear coat instead of an epoxy topcoat. The polyurethane will not yellow, but cost more, requires two coats and contains strong solvent fumes.

|

Links to Lots of MUST READ Information Articles About the Best Epoxy Floor Paints, Including Preparation, Alternatives, What Can Go Wrong, etc.

|

|

Bio Vee Seal - INTERNAL CONCRETE SEALER |

SOME OF THE SITES THE ABOVE LINK WILL DIRECT YOU TO |

|

Clear Top Coats - FLOOR CLEAR TOP |

Best Floor Epoxy - CLICK HERE |

|

Epoxy Quartz Floor - BROADCAST FLOOR |

Acid Etching - ACID |

|

Epoxy Paint Chip Floor - CHIPS |

Epoxy Paint vs. Floor Epoxy Paint - EPOXY PAINTS |

|

Epoxy Paint - SURFACE PREP |

Floor Basics/Options - START HERE |

|

Floor Epoxy - CATALOG PAGE |

Questions: ASK PROFESSOR E. POXY |

Questions? / Phone order?

/

EMAIL / CALL 603-435-7199 EST /

BUY

ONLINE

GOOGLE SITE SEARCH - Click here

Epoxy specific site search

Click here - YouTube video.

Learn about

Progressive

Epoxy

Polymers

Inc.

EVAL4U

- how to evaluate your epoxy

vendor -

CLICK HERE -

| NON STANDARD | FLOOR EPOXIES

|

AND LINKS | ||||

| PENNY FLOORS | basic no blush marine type epoxy | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| SHIPPING CONTAINER FLOORS | low v clear epoxy | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| INTERNET FLOOR LINKS SITE | floor links | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

|

"OLD GOAT" FLOOR EPOXY

Q & A |

floor focused help site | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| FLOOR EPOXY IN ONLINE CATALOG | start shopping here | CLICK HERE |

Legal Stuff / Returns

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option. Accessing this web site, and/or purchasing our products, grants Progressive Epoxy Polymers, Inc. permission to add you to our email newsletter list. You may opt out from the newsletter at any time (link to do so can be found on the newsletter).RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

** Quick EMAIL / ph 603.435.7199 EST / Google SITE SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOG / Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data and MSDS PRODUCT INFO / Epoxy Guru HELP SITE / Top Selling Products - FAVORITES * *

"The Right Epoxy fixes Everything!"

Visit our Subject / Catalog contents PAGE