Progressive Epoxy Polymers, Inc.

"Your Friend in the Epoxy Business"

Pittsfield, NH 03263

ALUMINUM PAINT - ALUTHANE MCU COATING

NO SALES TAX - You are

shopping in TAX FREE New Hampshire Recommended for

Shipping Container seal/coating of lead based paint surfaces Your Host and Tour Guide: Paul Oman, MS, MBA - Progressive Epoxy Polymers,

Inc. (floor epoxies,

marine epoxies, underwater epoxies, repair epoxies) Member: NACE (National Assoc. of

Corrosion Engineers), SSPC (Soc. of Protective Coatings) "Professionals helping Professionals"

since 1994

**

Quick

EMAIL / ph 603.435.7199 EST /

Google

SITE SEARCH

/ Buy On-line

TWO

STORES / Goto Contact

PAGE / Web Product

CATALOG /

Progressive Epoxy

HOMEPAGE / View

our VIDEO / Navigation Bar

REPLACEMENT / Data

and MSDS

PRODUCT INFO

/ Epoxy Guru

HELP SITE /

Top Selling Products -

FAVORITES * *

We are the only

technology based coating/epoxy/resin company that actively encourages your phone

calls, not just during our East Coast work hours but also after/before hours,

evening, weekends and even holidays. We're available when you are. We form a

personal relationship with our customers and freely share technical information,

how to-advice, product information and tips-and-tricks. Speak with a

non-salesman technical professional with over 25 years of experience in the

resin/coating/epoxy industry (no newbie staffer on the phone lines!). Floors,

tables, boats, leaks, rot repair. We handle it all!

We are an 'always available,'

one-on-one, technical/scientific, coating company (watch

our video). We are NOT one of those fluffy/slick mass sales firms the

dominate the internet selling cheap third party (made in China???), low end

epoxies and coatings with no real knowledge of what they are selling and

quotas to sell to as many people as possible. 603-435-7199 (east coast time).

NO SALES TAX - You are

shopping in TAX FREE New Hampshire

INTRODUCTION

Section 1 - INTRODUCTION TO ALUTHANE

Section 2 - Application notes

Section 3 - Test results

Section 4 - Commercial grade MCU vs. Home owner grade BUYER BEWARE!

Section 5 - Technical data

Section 6 - Feed back from users

Section 7 - Useful links

Quick Buy (cannot be shipped to California) --

Section 1 - INTRODUCTION

This is a commercial product group/type

(metallic Moisture Cured Urethanes - MCU) generally not

available to the consumer marketplace

| Order ALUTHANE at 603-435-7199 or at our Primary Web Store: EPOXYPRODUCTS |

What is an MCU Coating?

MCU stands for Moisture Cured Urethane and makes a very superior high performance coating. These are a unique type of coating much better known in commercial industrial painting circles than within the general public market. Most MCU coatings use tiny aluminum flake as pigment which gives them their classic silvery/gray color and enhances their remarkable properties.

MCU contain lots of solvents which aids in penetrating tiny cracks and crevices. The coating scavenges moisture from its contact surfaces and the air and undergoes an cross-linking molecular process which 'grips' or grabs onto surfaces for outstanding adhesion, even with poorly prepared surfaces. Removing internal surface moisture removes one of the key components necessary for rust development.

The resulting dry surface (aided by the stacking aluminum pigment platelets) provides a physical barrier to air and oxygen, another necessary component for rust to form. The result is a thin, hard coating that seals our air, water, salts, minerals etc. essentially encapsulating the surface It therefore is one of the best, easy to apply, rust and corrosion control coatings.

Its amazing adhesion results in a versatile coating well suited for use on steel, aluminum, concrete, fiberglass, wood etc. It can be used as a primer/sealer, a middle coat or a exposed as a topcoat. The aluminum pigmented versions have no UV issues, can be applied at low temperatures and operate at temperatures of up to about 400 degrees F. Besides being used as a rust stopper is also has applications on boats, roofing and flooring applications. In is used a lot in the industrial, automotive, marine and farm marketplaces. The AUTO RESTORATION market is one place these coatings are widely promoted within the 'DIY home' marketplace. My customers use on: aluminum boats (looks good and stops rivet leaks), to restore old, failing galvanized surfaces (boat trailers, farm equipment, galvanized water and farm stock tanks, are few common examples).

Use when

other coatings will not do - rust, moisture - sealing

and priming

Apply in temps as

low as 40 degrees or as high as 90 plus

A moisture cured urethane, aluminum metallic paint, Aluthane (tm) was specifically formulated as a primer over less-than

perfectly prepared surfaces. Use in temperatures down to 40 degrees F. However, this coating often ends up as an

aluminum colored topcoat. We're impressed with the ‘fresh galvanized' look it gives back to boat trailers. Also

makes aluminum masts and booms look new. Gives engines and other mechanical equipment that dealer fresh look (or

primed and ready to repaint status). On smooth surfaces it has a 'flat' galvanized look. On rough surfaces it has

a shiny silvery look. Unique penetrating urethane chemistry seals and covers rust, keeps it from ‘rusting back

through.' We know this is a great product - we can't get it off your hands even after days of normal washing and

wear. The real aluminum flakes can handle temperatures of several hundred degrees (and resists burning better than

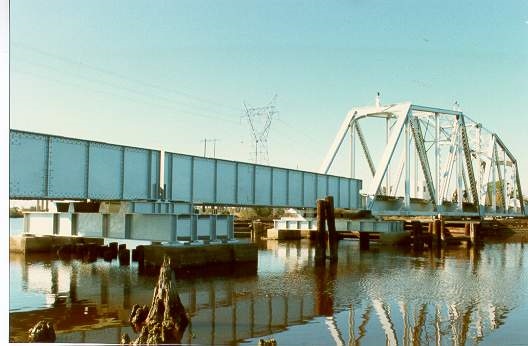

regular paint). Used industrially on large metal tanks, bridges, and piping with or without

top coating. A truly

unique primer AND/OR attractive metallic topcoat.

Because

of their amazing bonding, commercial painting contractors use moisture cured urethanes on surfaces that they cannot

prep as well as they would like to. You should too!

One quart units cover up to 100 square feet (about 75 square feet on rough surfaces and 100 sf on smooth).

|

Better product (here's why):

#1 we use 100% urethane resins - not the diluted resin systems in the popular Homeowner grade products

#2 Aluthane is more than 1/3 cheaper than those "15 rust" home products

#3Aluthane is much better coverage - up to 400 sf per gallon

Quick Buy (cannot be shipped to California) -- ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now - or call 603-435-7199

Section 2 - Application notes

It is recommended to sand if top coating and it has been over 16-24 hours since the application of the

Aluthane

(although personally, I don't).

My favorite uses: makes boat trailers look showroom fresh! Anti corrosive protection too! Bonds to wooden porches and RR ties like nothing I have ever seen.

When restoring/repairing old boats this is my favorite product. I put it on over the old wood or fiberglass after I've done a first pass fix on the serious problems. It goes on quickly and easily and without drips or sags, common with epoxy primers. With the hull now a uniform silver color I can easily see spots that need more work or sanding. The Aluthane sands well and quickly. It becomes darker when sanded. With sanding imperfections really stand out.

Note: Solvent based coatings (urethanes, enamels etc.) do cover Aluthane nicely on the first coat.

STORAGE - cures with moisture from the air, so an open can will thicken and harden within a few days. The

trick to

long storage is to squirt in an inert gas into the opened can (I use my shop propane torch).

On customer floated something on top of the aluthane to separate it from the air

in the can. Then

a sheet of plastic

wrap between the lid and the can rim - or you will not be able to remove the lid next time you attempt to open

the can! - proof of its extreme bonding properties! Most folks save up several

projects so that they can use up an entire quart or gallon within a day or two.

Other vendors don't mention this about MCU coatings. Better for them if

you just have to buy more of their product!

At the suggestion of a customer I've added thickeners to Aluthane with good success (an off label application)

.It then becomes a brush on 'thick build sandable primer' - which fills small dimples/edges, seams left behind

from more serious filling and patching projects. It dries quickly so it can be sanded down within a few hours.

Our fine micro-spheres makes a nice, easy to sand, mixture, but after sanding the 'broken spheres' leaves a porous

surface that needs to be sealed. Alternately, you can thicken with fumed silica. It takes more effort to sand,

but leaves a smooth surface that doesn't need sealing.

color changes from light gray to med gray when sanded. This is BIG DEAL, as it shows ‘high spots' on the surface. NICE!

Enamel paint can be applied nicely over

aluminum filled Aluthane.

Two coats provides outstanding corrosion - rust resistance. I use it on my steel, winter truck tire rims and

on old boat trailers. Makes them look like new galvanized trailers. Without top

coating.

Outstanding coverage - about 100 sf or more per quart (400 per gallon).

Aluthane metallic paint has a lot of solvent in it (like the ‘good old paints' of old) but can still be sold and used in all

states because of the solvent levels allowed for metallic coatings. This is helpful, but note that it cannot be

shipped by air so sales are essentially limited to the lower 48 states.

Also excellent as a concrete sealer or workshop floor coating!

Aluthane as a sealer/tie coat/color changing sanding

base coat when restoring Wood, Fiberglass, or Metal hulled boats

aluthane is the best coating for wood steps and porches - not its light gray color

Aluthane being applied to boat hoist

Aluthane on an old mower deck

2007 Aluthane™ coating of cast iron Thunder Bridge (dated 1880)

- About 5500 sf and 18 gallons of Aluthane™ -

Using Aluthane (aluminum filled) Moisture Cured Urethane

as a Primer on vinyl and wood (GOTO primer page)

Above - Old, dirty self stick vinyl floor tiles in work shop (light color on bottom) covered with

new "woody" self stick vinyl floor tiles after a primer coat of Aluthane over the old vinyl tiles

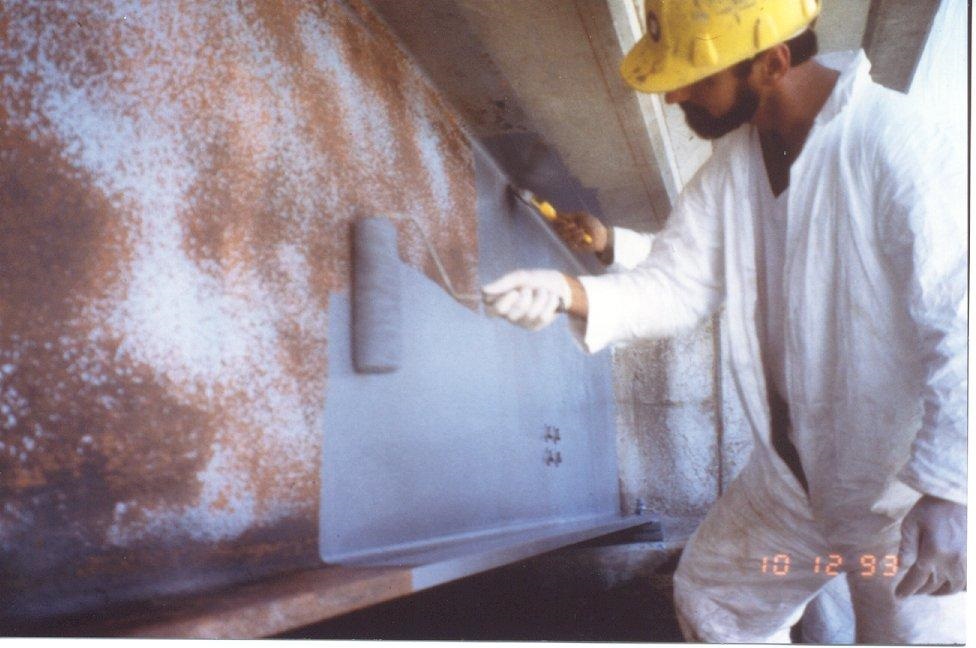

aluthane application over rusty steel

A common application for MCU aluminum coatings

Quick Buy (cannot be shipped to California) -- ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now - or call 603-435-7199

Section 3 - Test results

ALUTHANE ALUMINUM MCU PAINT TEST RESULTS:

I coated an Armstrong brand commercial floor tile (12 inch by 12 inch), as well as a piece of plywood, with one coat of Aluthane and submerged it in a freshwater pond for 5 months. Both samples were perfectly intact (no peeling, blistering, softening, etc. at the end on the test. While urethanes are generally not considered suitable for immersion applications, this product appears to work fine underwater We cannot officially warranty it for immersion, but I personally now feel comfortable enough that I would use it on a dinghy boat bottom, boat mooring, submerged pump, etc.

I've found it also makes a great primer and sealer under latex or enamel (an alternative to a solvent thinned epoxy

primer) - although because of its medium dark color it may take 2 coats to cover.

Especially over epoxy when you are going to topcoat with enamel. Sometime there are problems with enamel over epoxy

-

Click Here

-- Aluthane metallic paint / aluminum paint is becoming my favorite primer/sealer under all solvent based coatings.

Results of about a 1.5 year test of various coatings and primers in outdoor exposure. - The actual test of many different coatings and different levels of solvent thinned epoxies were inconclusive, however, the patch of Aluthane looked like new. If you're looking for a coating you can just sort of slap on without a lot of surface prep and have it last a long time (even underwater) - use our Aluthane™.

Quick Buy (cannot be shipped to California) --

ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now - or call 603-435-7199Section 4 - Commercial grade MCU vs Home Owner Grade

Commercial vs. DIY MCU Coating Products

Given the outstanding and time tested performance and properties of MCU coatings in serious commercial setting it is not surprising that companies have attempted to move this product into the DIY/Home-Boat Owner market. This market is less knowledgeable and will accept lesser quality and overpriced MCU coatings compared to the commercial/industrial marketplace.Warning Flags:

* Very slick web sites that suggest their product is unique and one-of-kind and that you cannot find anything even remotely similar. Some sites really play up MCU chemistry, others hide it, thus implying how 'magical' and special their standard MCU coating is.

* Fancy product names and colorful labels that suggest a Madison Ave focus rather than no-frills commercial roots.

* Prices in the $150-$200 a gallon range. No MCU coating is that expensive to manufacture, especially for large companies. These folks are making $100 plus profit per gallon from you (with 'discounts' and 'free shipping' making hardly a dent in their profits). No commercial user would pay these outrageous prices for a gallon of an industrial coating.

* Check product coverage. These are thin products, due to their chemistry they don't need to be thick. But the general public usually thinks thicker is better. The thicker the product the more you use and the more you will have to purchase (at those extremely high prices). If coverage numbers are given make certain they are real life numbers and not "theoretical coverage" numbers. The theoretical coverage for 1 gallon of water at 1 mil thick is over 1600 square feet.

* One thing that cannot be easily established, but should be lurking in the back of your mind is the polyurethane resin used in the manufacture of the coating. Top-of-the-line, commercial/industrial MCU coatings, like our Aluthane product, use 100% polyurethane resin. MCU coatings can be manufactured with diluents and other low cost additives to reduce the amount of polyurethane resin in the manufacturing process (like adding water to the whiskey!). The result is still a good MCU, but not a great one and not one formulated for maximum performance, but rather for better profits. One of our 'regular' 30 gallon a month Aluthane MCU customers stopped purchasing for about 5 months, presumably testing alternative products. They returned to us most likely because of the higher purity/quality and reasonable price of our Aluthane (tm) MCU.

One of the major differences with our Aluthane MCU and other aluminum MCU coatings is that we use 100% urethane resin and all (or just about everyone else) thins or dilutes their urethane resin so that the end product is less than 100% urethane resin and aluminum. The difference with these cost cutting/profit enhancing measures is a product that just doesn't perform or last as long as our pure resin system. Over time the differences are easy to observe and I have actual customers that have tried the competition, but then come back to our Aluthane MCU.

Quick Buy (cannot be shipped to California) --

ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now - or call 603-435-7199Section 5 - Technical Data

More Tech Info:

Millions of dollars are spent each year on the maintenance

of painted steel in this nation. To reduce such costs, the use of climate-tolerant, durable coatings has become

essential to ensure extended painting seasons and coating lives.

Moisture Cure Urethane Aluminum

Paint Primer / Finish Product

Description

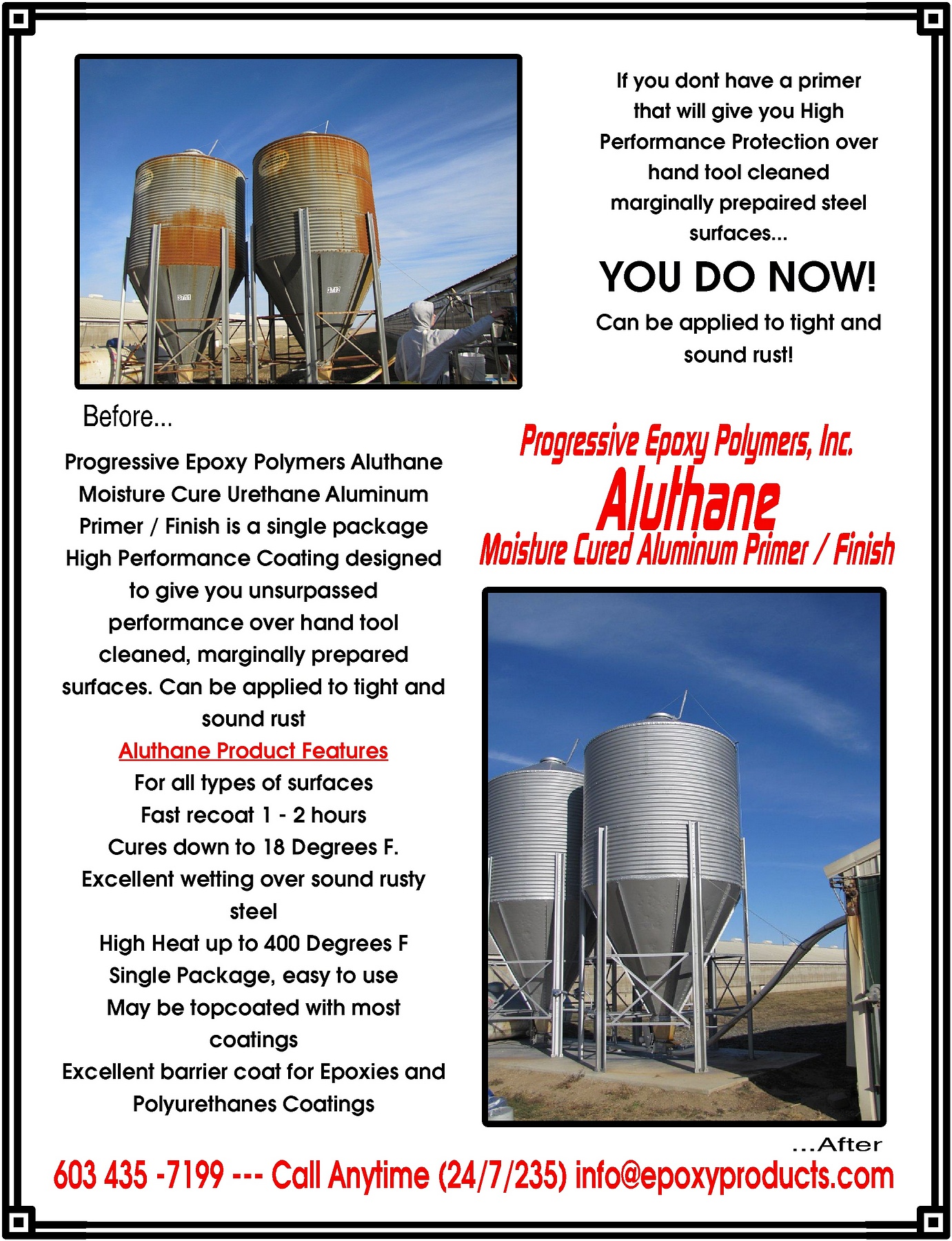

Progressive Epoxy Polymers Moisture Cure Urethane Aluminum Primer / Finish (Aluthane™) is a single package High

Performance Coating designed to give you unsurpassed performance over hand tool cleaned, marginally prepared surfaces.

Moisture Cure Urethane Aluminum Primer / Finish Product

Features

For all types of surfaces, steel, weathered galvanized steel, (anti corrosive) aluminum, select plastic substrates, wood, concrete,

Fast recoat 1 - 2 hours

Cures down to 18 Degrees F.

Excellent wetting over sound rusty steel

High Heat up to 400 Degrees F

Single Package, easy to use

May be top-coated with most coatings

Excellent barrier coat for Epoxies and Polyurethane Coatings

Background

Moisture-cured urethanes were designed to protect steel from corrosion. Progressive Epoxy Polymers urethane aluminum

formulations originated in Germany and were brought to this country in the 1970s.

These coating systems are known for their adhesion to steel and good abrasion resistance. This coating material

consists of a single resin component that forms cross-linking polymers through a reaction with moisture from the

air.

Progressive Epoxy Polymers urethanes offer convenient application properties. It come in single packages and has

longer shelf and pot lives than most other coatings. In addition, these fast top-coaters have low-temperature and

high-humidity application properties.

Performs as a primer

As primers, Progressive Epoxy Polymers moisture-cured polyurethanes are pigmented with aluminum.

Aluminum pigments provide high resistance to water vapor transmission and gas and ion penetration.

During application, the pigments in moisture-cured urethanes align themselves more or less parallel to the substrate

in closely packed layers. After the coating has cured, the overlapping pigment particles form a dense barrier against

moisture and other corrosion promoters.

The pigment layers also reinforce the coating, relieve stresses within the paint film and improve intercoat adhesion.

Alignment of the pigments, combined with the reaction of the isocyanate group with crystalline bonded water in

rust, allow moisture-cured polyurethanes to offer enhanced corrosion resistance and strong adhesion, even to less

than ideally prepared substrates.

Minimal surface preparation

One of the major advantages of moisture-cured polyurethanes is that they can be applied to steel substrates with

less surface preparation.

Abrasive blasting to white metal is without question the best method of surface preparation, but is also the most

expensive. Most often, power-tool cleaning is all that is required for these types of urethanes.

In comparison to abrasive blasting, the amount of waste generated by power-tool cleaning is dramatically reduced,

as is the expense of shrouding the structure and cost of waste disposal.

Excellent chemical resistance

In addition to impressive physical characteristics, moisture-cured polyurethanes offer excellent chemical resistance.

Contact with liquid hydrocarbons such as xylene, gasoline and mineral spirits have little effect on properly formulated

moisture-cured coatings.

Oxygenated solvents such as ketones, esters and alcohols can soften the coatings in immersion, but the films can

quickly recover once the solvent is removed. Many of the systems on the market today are suitable for long-term

exposure to splash and spillage of these solvents.

Abrasion Resistance

Method: ASTM D4060, CS 17 wheel, 1000 cycles, 1 KG Load

Result: 18 mg Loss

Adhesion: Cross Cut

Method: ASTM 3359

Result: Passes 5

Adhesion: Elcometer 106

Method: D4541

Result: Exceeds 500 PSI

Dry Heat Resistance

Method: ASTM D2485

Result: 400ºF

Flexibility: Conical Bend Mandrel, 180º Bend

Method: ASTM D522

Result: Passes 1/4”

Impact Resistance:

Method: ASTM D2794

Result: Direct – 160 in. lb.

Pencil Hardness:

Method: ASTM D3363

Result: 4H

Salt Fog Resistance:

Method: ASTM B117

Result: Passes 1200 hrs

Accelerated Weathering

Method: ASTM D-4587, QUV

Result: Passed: 1500 hours

| THIS PRODUCT | xx | EMAIL US | xx | |

| air shippable | cycloaliphatic system | |||

| no nonyl phenol | epoxy adduct system | |||

| multi curing agents | bulk pricing | |||

| solvent free | no Calif. sales | |||

| 2 part epoxy | 2 part poly | |||

| apply underwater | bubble breakers | |||

| favorite(s) product list | xx | data sheets | xx | |

| PACKING - jugs/bottles | PACKING - cans | xx | ||

| find in non marine cat | xx | find in marine catalog | xx | |

| PRICES/ind/commercial | xx | PRICES/marine section | xx | |

| BUY online | BUY online | xx | ||

| home page | xx | contact page | xx |

---- Note that problems with Aluthane are often a result of: excessive moisture, excessive thickness (applied very

thick), or excessive temperature (too hot). The result is usually pinholes in the

Aluthane. Also, if exposed to

the weather for more than a few days, it really needs to be sanded to provide a good surface for any topcoat paint.

Quick Buy (cannot be shipped to California) --

Section 6 - Feedback from users

"Hi Paul,-- We have been using the Aluthane product for 6 years now and it has been a blessing for our business." (11/14)

"A very pleased user of Aluthane and your epoxies" (primer on old cars)

Craig - Houston, TX - Oct. 2016

"Paul, just thought Id let you know, used Aluthane on bottom of a fiberglass/ epoxy hull repair, on my high speed powerboat tunnel cat. Left it on a mooring in Maine for about a total of 3 months (8 times for 3 week stretches) since last May. Paint is still perfect - submerged 3 weeks at a time." - Dave 10/16

"I use your Aluthane as a sealer for fabric-covered airplanes. We use dacron, and Aulthane wets out beautifully on dacron. It also fills the weave, another desirable characteristic. The aluminum pigment protects the dacron from the sun....otherwise dacron deteriorates rapidly. I have seven years experience with aluthane, and it is doing a very good job.

Many aircraft paint systems use finely powdered aluminum as a blocker, and this is a proven technology. The paint must stick well to dacron, retain good flexibility for many years, and generally be a tough coating. It should seal the fabric, reducing any airflow (air leakage) to a minimum. As a bonus, the paint system should be amenable to repairs...important for rag/tubes because sometimes we ...ahem ! ...make mistakes. In my experience Aluthane meets these requirements.

Aluthane wets out on dacron beautifully. It penetrates and seals, too. I made up a 18" x 20" test panel and stretched 2.7 oz aviation fabric at 300F. The pix show front and back of Aluthane applied with a fairly wet foam brush. Streaky. I'll go with a drier brush and cross coat on the next test panel.

Aluthane is compatible with acrylic latex house paint. The red is Valspar Duramax "Quite Red" , sourced from the Home Depot Aviation Specialties department. In the pix it is applied with a fairly wet 4" foam brush. My next panels will be sprayed with typical latex paint equipment. I used a 3/4 dowel and poked it pretty hard into the back of the Alu/Valspar test strip, moving it along to test flexibility. Just fine on that score. I'll tell you five years from now if it remains that flexible!

I had Aluthane on a dacron outdoor test panel for five years (see below). It was still in good condition after five years, and continued to adhere well. I flew an airplane for four years with the Aluthane topcoated with Polyfiber Bahama Blue. Both the Aluthane and the topcoat remained flexible. Seems to me that Polyfiber paint sticks pretty well to a fairly fresh coat of Aluthane and less well to an aged (say, two weeks) coating.

Aluthane also appears to stick like crazy to both aluminum and fiberglass!"

--- JP (10/14)

|

Good Afternoon Paul, Just wanted to send a note that you should share with new customers about the ALUTHANE product that you recommended for a project I was bidding. I was approached about repainting the loading dock diamond plates at an overnight package service terminal. The original paint was only a little over three years old and the plates were very rusty and showing extensive wear. The customer would be an important add to my client base so I wanted to make them happy with our first shot. I originally contacted you about using an epoxy coating but you strongly suggested the Aluthane moisture-cure urethane as the best solution. You couldn’t have been more correct. After following all the necessary preparation steps, we applied two coats of the Aluthane to all the surfaces, including areas that we just couldn’t surface grind or effectively reach. We did power-wash and dry all the surfaces but that meant some spots may still have surface rust that would be painted over. To see the final results, you’d swear that we installed new plate material rather than repaint it. It is just that good! The stuff is bullet proof! Thanks again for helping to make us look so good! -- Bill -- AXXB Construction Services, LLC 11/17 |

|

ALUTHANE - aluminum MCU (moisture cured urethane) super coating |

| Paul, (11/15), Just wanted to let you know how well Aluthane works as a coating for a boat anchor. We have a 41 foot DeFever trawler with a 55# SuperMax anchor that dates to the late 1990s when they were first produced. Over the years and a lot of anchoring in various types of bottoms, the galvanized coating on the anchor had deteriorated to being almost non-existent and the underlying steel was starting to rust lightly. It's almost impossible around here (east coast of Florida) to get anything regalvanized, so looked for alternatives. Aluthane jumped out at me as a good choice for a test. Before we departed on our latest 4500 mile cruise from Florida to Maine and return, I "painted" the SuperMax with two coats of Aluthane after brushing off all the rust I could and coating it with Ospho prior to the application of Aluthane. Five months, lots of rain and ocean spray, and 51 nights at anchor in various types of bottoms from sand and gravel and rock to mud, the Aluthane had worn off at only the very tips of the anchor (the area that digs into the bottom) and exposed the underlying steel. The vast majority of the surface area of the anchor was still being protected by the Aluthane. I just finished adding two more coats and it looks great! |

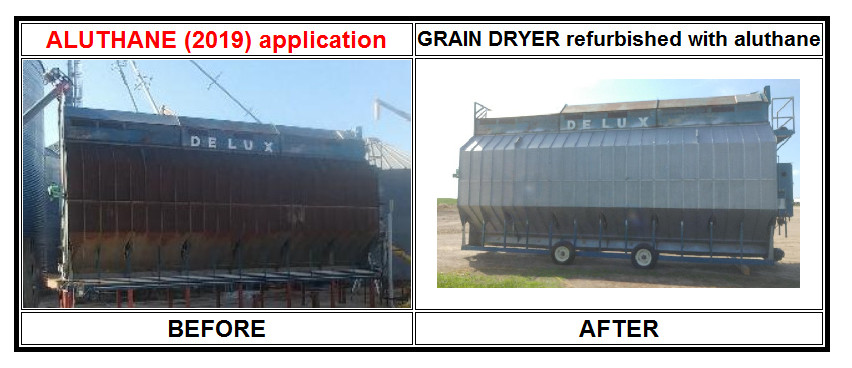

Aluthane before

aluthane after

|

ALUTHANE (tm) ALUMINUM PAINT moisture cured urethane |

stops leaks too! |

|

Before Pictures |

After Pictures |

|

|

|

|

|

|

|

|

|

Before and after Aluthane shots

(works just as well on old boat trailers too!)

aluthane and aluminum boats web page CLICK HERE

Paul-

After prepping, there was still some residual paint that was welded

on and

couldn't be removed without stripper. Since the product is designed for

'less than perfectly prepared surfaces', it didn't require messy stripping

chemicals or excessive prep work.

The Aluthane has an nice aluminum sheen and cures very hard. It has a

watery consistency and spreads easily. It filled pinhole size gaps, making

the surface airtight. I was able to mimic the original paint scheme

because of Aluthane's aluminum color. I used it as a primer and topcoat.

Aluthane made my 50 year old boat look new again!

Very satisfied, Matt

Tom wrote (10/2008):

Thanks Paul; here are a few comments on the Aluthane.

I was looking for a product to use on the 4" steel pilings on a newly constructed boat house. I wanted to

extend the life of the piles and the overall structure since the boathouse cost roughly $50K to build. Aluthane

was recommended. At the time, the water was down around three feet from normal pool so I was able to paint roughly

4 feet of the piling that was exposed. For prep, I used a simple paint scraper to smooth off the rough, loose rust

and then a wire brush. I did not put a lot of effort into preparation. Total prep time per piling was no more than

3-5 minutes. I used a 3" roller and rolled the Aluthane on. Again, very simple and quick. The

Aluthane will

run, so you do have to roll it on and smooth any runs with another quick roll over.

The results looked great. Basically a shiny aluminum look. When the lake came back up to pool, I kept watch for

any signs of deterioration and saw none 12 months after application. The water went back down even further in the

last few months, so I was able to inspect much closer and even apply the Aluthane further down the pilings. There

was absolutely no rust through with 12-15 months of submersion.

The Aluthane surpassed all expectations and I now am in a wait and see mode on how long it will last before corrosion...no signs yet. I know its not advertised for submerged applications, but I can attest that it works very well for at a minimum of one year in fresh water applications. Excellent product that requires very little prep and seems to be very effective.

Hi Paul,

I was working on the boat today and couldn't help but notice how sharp my aluminum hardtop (still) looks after

a very harsh summer of hard work on the salty ocean and a long New England winter exposed to the elements.

I remember the day I finished welding my hardtop and sat baffled as to how to finish it. You see, the hardtop frame

was comprised of a half cut-up Mako tower (anodized aluminum) and scrap 6061 aluminum, all TIG welded together.

With little to no prep, aside from a light sanding and a wash with alcohol, I was able to brush on (stippling)

two coats of Aluthane in a day and have the boat launched a week later. Since then, the frame has seen rope chaffing,

scrapes, climbing crew with abrasive sandy shoes, and harsh sun and seawater. The finish has never worn through

and shows no signs of damage.

It has held up marvelously. So well in fact, I go out of my way to find things to paint with Aluthane. So far,

I've painted my engines heat exchanger, primer my manifolds and risers, painted parts of my galvanized trailer

including the wheels, and various mixed metal hardware on my boat.

I've recommended this product to others looking for a tough coating that can take a beating. A little goes a long

way with Aluthane and it is almost funny how easily it goes on, rolled or brushed. One caveat, brushing will show

brush marks so I usually stipple the surface with a brush with its bristles cut way back (or roll it on). Continuous

mixing is key, too. It isn't glossy which is nice in some cases.

Paul 4/09

From comment section of 6/2010 online order for 1 gallon of Aluthane: "Returning (vendor note - a past customer). Spiral stairs near ocean. Wonderful coating that resists corrosion.

John (2/16/2012 email): A Wonderful Product!! Love Using It For A Little Of Everything!!! Proud To Buy American Products!!

My first experience w/ Aluthane was on my 1966 Starcraft boat....then with the left over quart I did the main door on my garage.....after that....I still had enough to apply a coat onto my rear bumper of my F250. This time around.... I used 1 quart again on: The in and outside panel of a retired U-Haul Truck (33 5/8 in. x 6 1/2 ft).....all the interior wall panels of the box truck (it's a 14 ft. box with grandmas attic)....and a 80# saddle propane tank. It's been an average of 28* up here for a high and it applied beautifully.....drying time is slower (I expected this)....but it coated just as smoothly as if it was 75* and sunny.

I totally agree.....b4 I crack a 1 quart container....I make sure I have enough things to coat so I don't hafta waste it in the garbage. I've been telling as many people as I can about Aluthane (and about you guys and galls).....telling them what I've been using it on and how nice it looks...and how smoothly it helped water proof my 46 year old boat and with a teeny bit of help from Marine Goop. My boat flows so smoothly through the water.....you would have never guessed that it leaked pretty good b4 the Aluthane and Goop.

I just hope and pray that this Economy and World Govt. doesn't shut you guys and gals down. That will be a VERY VERY SAD DAY for all the DIY's and commercial and industrial accounts you deal with on a regular basis.

Keep up the WONDERFUL WORK!!! Love the product so much!!! OMG.....I wanna coat everything exterior with it.... LOL. But seriously... when I get a chance.... I will be using the 1 Gallon Aluthane to do both of my porches. Have a great day and year. And blessed be us all.

John

I received an email on aug. 7th from Sgt. Josh X reminding me how well Aluthane works on floors. "Hello, Have used aluthane before and it is an amazing product. Applied it to a shop floor 6 years ago and no chips or scratches."

Hi Paul,

I just finished painting my horse trailer (sided with FRP) with your Aluthane primer and thought I’d send you a

'before' and 'after' pic.

I was so happy with the product, I decided not to even topcoat it, lol! My husband wants me to order LOTS more;

after seeing how beautifully it covers, he’s finding lots of projects around the yard that will benefit from this

awesome primer. I spent a lot of time sanding, then used your Captain Tully’s crack filler, smoothed all over the

fiberglass sides, which were badly checked. One gallon of Aluthane applied by a combination of roller and brush

did the whole two-horse trailer very nicely. I would recommend it to anyone and will use it over and over again.

Thanks for your input on the project!

Mary

UPDATE 10/20 MARY: "I'm delighted to still see the pic of my horse trailer on your aluthane page. Now I'm planning to treat the underside of my Lexus SUV against corrosion. Great stuff!"

"Two weeks into

our 10,000 mile shakedown trip and the

aluthane trailer looks great and we are so

happy with it. Thanks for your help and

materials.

Its my own design but borrowed heavily from

many models I've seen. I created my own

plans but did most of build from all my

pre-thinking and envisioning. The enclosed

portion is the size of a queen bed 60x80.

Over length of structure (minus tongue) is

9’3” and the body is 5’ 1” wide.

It has a 110 and

12v system with a converter. I charge the

battery with tow vehicle while driving and

110 shore power when in a campground that

provides. So far I’ve gone 2 plus days

unplugged from 110 and all systems still

work great."

David

Aluthane aluminum paint / sealer works on plywood panels too!-

above - side panels of mini tear-drop trailer

below - trailer being assembled

"Hello, I have used Aluthane to coat machinery and think it’s a marvelous product."

Aluthane as a primer under a VERY HIGH END FINISH - (user notes)

Mon, 24 Nov 2003 18:42:56 -0800

From: Cal <>

"The brush marks from the brush application of the Aluthane put me off and I had to cover them before the Aluthane got to maximum hardness. The job is done now, and a nice finish, but I have a few observations for top coating to a glossy finish that I would like to share. I did my bench top a month ago, and it is different by a LOT from the boat coating I saw happening.

The Aluthane needs to be rolled on, and not brushed to flatten out well. I used a phenolic core 9 " by 1/4 " nap foam roller, 3/16" would be even better for a lot less texture than the brush streaks that were left. A good smooth roll down my bench top (or hull) faired everything in well.

Let it set until it can be over coated, and now I think for a top coat it MUST be over coated with clear to look the best. For top coating the Aluthane, the desired result is to have the clear finish help smooth out any remaining roller texture. Since there is no pigment, it is much easier to carefully polish the clear coat smoother, and leave a satin or semi gloss finish without smearing or scratching the base coat. Some tests show that a very slight "orange peel" textute is actually faster, as it disturbs the water barrier layer just next to the hull, and holds air under the hull at speed. Sounds good, saves work!!

My "test" work bench is now the bulletproof finish that you talked to me about. Thanks for the good stuff!

I will order more epoxy today.

Best wishes for Thanksgiving, and Christmas -- Cal

From the I.BOAT.COM forum - 12/22/02

I have nothing to do with this company, but I tried their Aluthane primer and it is great.

https://www.epoxyproducts.com/5_urethane.html

This stuff works even better than they claim it does. I first tried it on a vinyl top of a old Pontiac Bonneville

(w/455 engine) that was mechanically sound but the top leaked like a sieve due to rust under the vinyl. The options

were fiberglass the top to seal the vinyl or paint over it. I tried aluthane, it worked. it water proofed it with

two coats, and even looks + decent. Now I have a high speed tow vehicle that ride four in comfort and pull my 21

foot cc.

I have also used aluthane on boat trailers and the floor on my small aluminum row boat. As I said it is even better

than they claim it is.

Sept 06 email

"I just wanted to tell you again how thrilled

we are with the aluthane paint.

I had about 1/2 gallon left in the original can from painting the boat house steel framing, I'd put a couple layers

of waxed paper between the lid and the can and sealed it as tight as I could... it worked, some of the paint settled

to the bottom, but it all remixed just fine. We used it to do some touch up painting and paint a new beam I had

to weld in to make the boat lift work. While we had the paint out, my wife looked at the abused old pontoon boat

sitting there, and before I knew it, she had painted the front of the pontoon aluminum sheet metal "siding"

with the aluthane. It looks amazing! basically no prep, and applied with a cheap disposable brush, it appears to

have been sprayed on, shows the grain of the siding beautifully, and just looks great!

We put the remainder of leftover paint into canning jars with little or no air above them, hopefully it will keep

that way for some time... I have a feeling we'll be painting all the pontoon siding at some point in the future!"

Hi,

The Aluthane is incredible, I used it on an old aluminum canoe and it is the best coating I have ever used. I will

be using it on a very beat up aluminum boat I just bought.

Thanks Vinny

5-2013 email from "Storm" - a long time customer:

"Aluthane does a beautiful job on concrete floors!"

(note from webmaster - I've used it on wood floors in a shed and was impressed. And after years of trial and error testing, I use it on the wood decks around my house - on wood it sort of looks like a light gray. Holds up better than any other paint).

What others on the internet say about ALUTHANE

Quick Buy (cannot be shipped to California) --

ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now - or call 603-435-7199Section 7 - Useful links

|

ALUTHANE aluminum moisture cured urethane |

|

A favorite with the trailer and Tear Drop Trailer communities |

| TEAR DROP LINKS: https://www.tnttt.com/viewtopic.php?f=21&t=44339---- |

|

|

Also find this product on our google Favorite Coatings PAGE

Data/MSDS sheets for this product

Find in Marine Catalog

Find in Home/Commercial Catalog

This product is featured on the GreatThings4u.com website

Additional product information/mentions about ALUTHANE can also be found at the following site(s) -

https://www.paints-coatings-epoxies.com/a_aluthane_aluminum_paint.html

Quick Buy (cannot be shipped to California) --

ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now - or call 603-435-7199ON-LINE CATALOG HOMEPAGE.

Inside Our non-marine, commercial, DIY Catalog:

corro coat FC 2100; water gard 300; CM 15; crack coat™; liqua tile 1172 potable water; water prime

Find Corro Coat FC 2100 and Water Gard 300 epoxy in our Best Selling - fix anything Catalog

wet/dry 700; splash zone A-788, epoxy cream; splash zone a-788

Find Wet Dry 700 epoxy in our Best Selling - fix anything Catalog

low V epoxy; basic no blush; ESP 155; Bio-Clear 810; epoxy clear top resin

Find Low V, Basic No Blush, and ES 155 epoxy in our Best Selling - fix anything Catalog

Aluthane moisture cured urethane; Acrylic Poly UV Plus and other 2 part polys ; Capt. Tolley's creeping crack sealer; india spar varnish;

Find Aluthane in our Best Selling - fix anything Catalog

fumed silica; fiber fill; micro balloons/micro-spheres; graphite; wood flour; EZ thick, rock flour;

water activated pipe wrap; TA 661 solvent-free epoxy brush cleaner; fiberglass tape/cloth

short nap epoxy rollers; epoxy/stone deck resurfacing roller; 1 inch foam brushes; 2 inch bristle brushes; tongue depressors

Legal Stuff / Returns

NOTICE: Legal notices, Terms of Service, warranty information, disclaimers, health warnings, etc. are required reading before using web site, ordering and/or using Products. Any such use and/or ordering, online or by telephone, shall constitute acceptance and knowledge of all such terms.

CLICK HERE to access these terms. Please note: Whenever you purchase from this web site, and with each new purchase, you are granting us full and complete permission to add you to our email newsletter list at our option.RETURNS: call or email for authorization to return. Returns are subject to a 25% restock fee. Customer pays return shipping and must comply with federal DOT shipping requirement/labeling for hazmat epoxies under penalty of fines and legal action.

Quick Buy (cannot be shipped to California) --

ALUTHANE (tm) MCU - ALUMINUM PAINT -- Now - or call 603-435-7199

|

|

Progressive Epoxy Polymers, Inc.Pittsfield, NH 03263EPOXY PAINTS AND RESIN SYSTEMS - 1 AND 2 PART URETHANES - COATING SUPPLIES

|

|

Quick Send EMAIL / phone # 603.435.7199 EST / Google SITE ONLY SEARCH / Buy On-line TWO STORES / Goto Contact PAGE / Web Product CATALOGS |

Progressive Epoxy HOMEPAGE / View our VIDEO / Navigation Bar REPLACEMENT / Data-MSDS TECH INFO / Epoxy Guru HELP SITE |